There are several considerations when choosing an infill pattern for a print. Object strength, time, material usage, and print weight are a few examples. One of the obstacles most people walk into while 3D printing is, how to make parts as strong as possible while consuming as little material possible. For this edition of 30 on 3D, Senior R&D Engineer, Peter Montgomery, solves this problem by explaining how to create custom fill patterns in Insight.

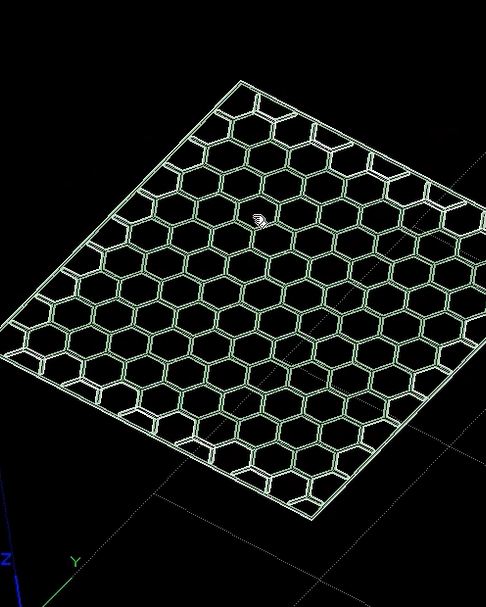

3D printed objects aren’t required to be 100% solid. Instead, there is an option to print a low density internal lattice structure that preserves rigidity. Printing at a higher infill density will of course make your object stronger, but at the cost of more materials and longer print times. Insight, Stratasys’ premiere FDM control software, allows you to choose and customize from a variety of infill patterns and densities; a popular choice is the hexagonal (honeycomb) pattern. To learn how to optimize your infill, follow these quick and easy steps:

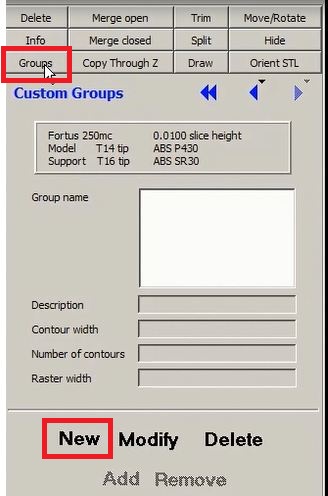

1. Click on “Groups” to create a custom group and then click “New”.

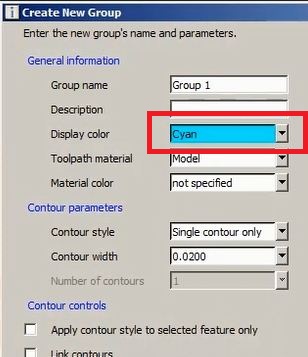

2. This will open up a “Create New Group” window. Change the “Display Color” to Cyan so you can distinguish the infill from the outer shell of the part.

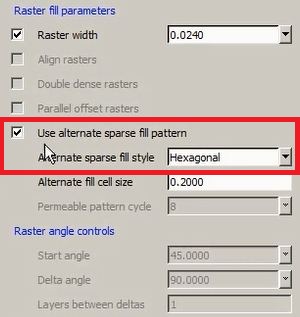

3. Click on the box that says “Use alternate sparse fill pattern” and make sure “Hexagonal” is selected in the “Alternate sparse fill style” drop down.

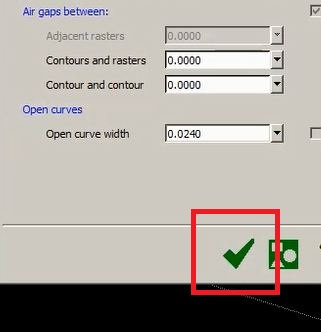

4. Once these settings are set, click the green check mark at the bottom to save.

5. Now click and drag to select a few layers of your print.

6. Once highlighted, click add to apply the custom fill pattern.

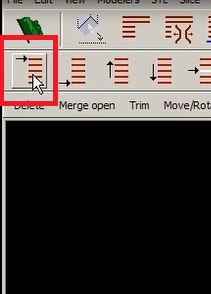

7. Select only the top layer by clicking the “Scroll Up” button at the top left.

8. Finally, slice again by clicking this icon.

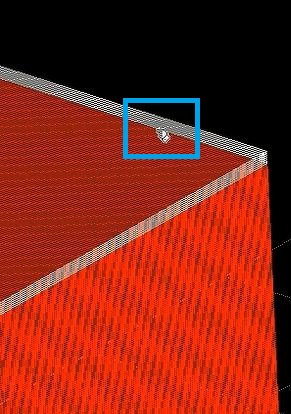

9. Hexagonal fill pattern is applied.