The functional prototype diaphragm in the foreground was made using Santoprene from the 3D printed injection mold. The CNC tool for the same part is in the background.

Did you know that you can create up to 97% lead time reduction for the production of injection mold tools for prototype parts by introducing 3D printing into your tooling process? At Whale, a leading manufacturer of water and heating systems, injection mold tools are being 3D printed in less than twenty-four hours using their Stratasys Objet350 Connex Multi-material 3D Printer, at a fraction of the cost of producing metal tools.

Jim Sargent, a 3D printing technician at Whale, explains, “Traditionally, our lead times for metal tools were somewhere between four to five weeks and came with significant production costs. As a result, our R&D process was very time-consuming and fundamentally slowed down the launch of new products. With our Objet Connex 3D Printer, we are now able to design our tools during the day, 3D print them overnight and test them the next morning with a range of end-product materials. The time and cost savings associated with this new tooling method are significant.”

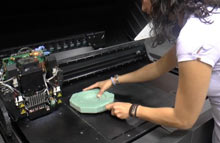

3D printed injection mold for a diaphragm being removed from the Objet350 Connex

Multi-material 3D Printer

Patrick Hurst, Managing Director at Whale said: “Looking into the future, 3D printing is hugely revolutionary in terms of how we are going to operate as a business. We have already seen the technology take months off our product development process and that in turn minimises risk. In fact, I estimate that we’ve shortened our R&D process by up to 35% with Stratasys 3D printing solutions… on top of the 20% we’re already saving in terms of our design work…”

3D printed injection molds for various industries produced at Whale with Stratasys 3D printing using high temperature ABS materials.

Nadav Sella, Solutions Sales Manager at Stratasys said: “We are seeing an increasing number of customers exploring the potential that 3D printed injection mold tools offer. In addition to the dramatic cost and time savings potential, our Digital ABS tools enable companies to produce parts in the real end-product material, ready to test even in the prototyping phase. Our customers can therefore make quicker test iterations and bring products to market faster.”

To learn more about 3D printing and injection molding, watch this webinar-on-demand provided by Stratasys.