Tooling is an incredibly common 3D printing application, for good reason. Whether you’re looking to create parts for manufacturing, assembly, or inspection, we can help. Purple Porcupine’s typical lead time is 3-5 business days, meaning your custom part can be designed, printed, and put to use in under a week. In this blog post, we’ll look at why drill guides are an effective use for additive.

Why Drill Guides?

Drill guides can allow some CNC processes to be rerouted for manual drilling, to prevent bottlenecking in CNC departments. Manual drilling processes can also benefit from the use of drill guides, as the guides specify the exact drilling locations, meaning you won’t have to mark the drill locations.

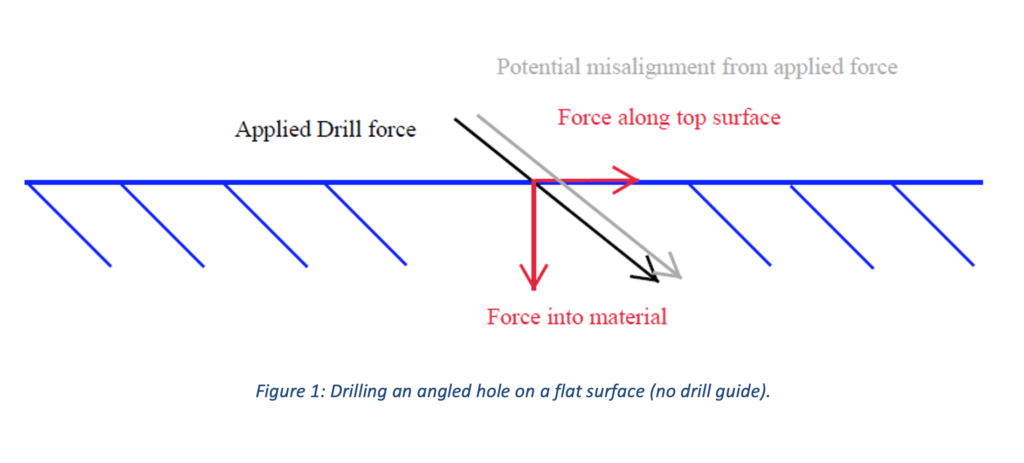

Ever try to drill an angled hole on a flat surface? Even with a pilot hole, the entry angle for the drill bit will want to push the drill along the surface, rather than into the surface. This can result in the hole being misaligned or out-of-round, as the drill bit chatters along the surface of the material.

Even with precise measurements and a pilot hole (Figure 1), the force applied along the surface of the part will result in the drill bit sliding out of position. With a guide restraining the drilling location, this process becomes significantly easier.

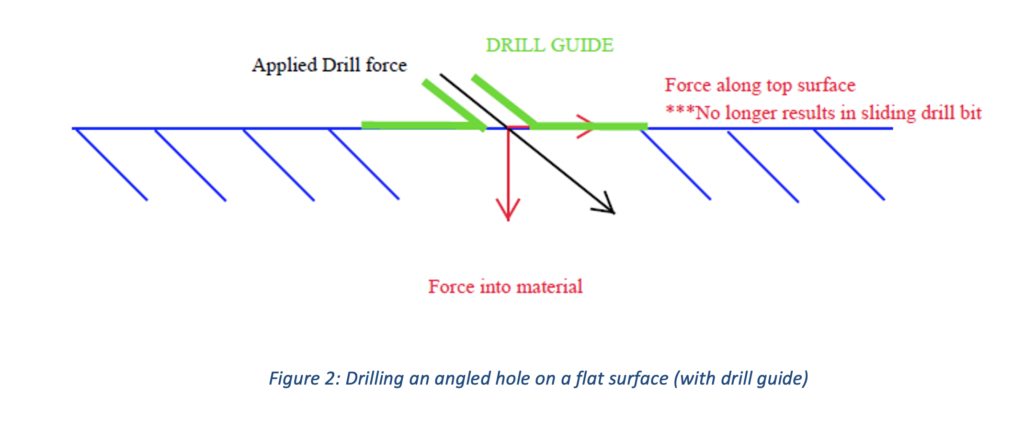

With the addition of a drill guide, the drill bit is restrained from shifting beyond its original position. While the drill will want to slide the guide will prevent the movement (Figure 2). A drill guide will improve your manufacturing quality and serve to prevent workplace injuries from occurring.

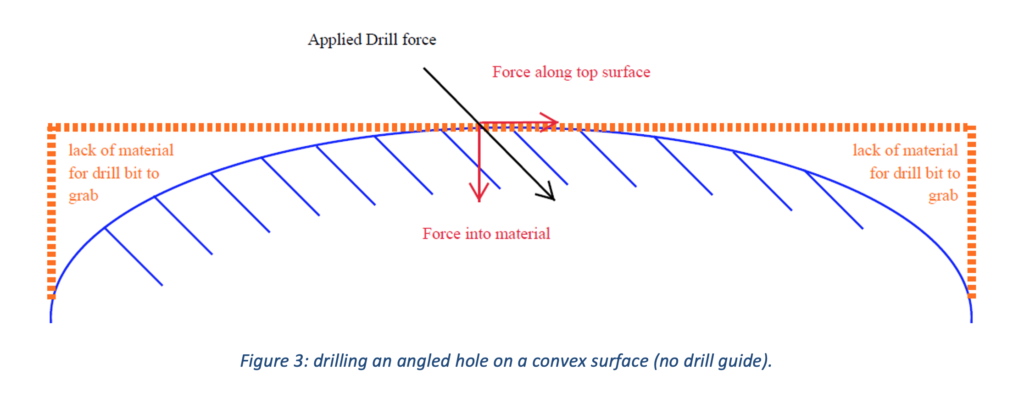

Now, imagine trying to drill an angled hole on a convex surface (Figure 3). The slope of the surface means that there is less material for the drill bit to grab onto, as more force is being applied into the material. This can result in the drill slipping from the top of the surface rather quickly, which can lead to part damage or, worse, operator injury.

Reducing and eliminating the chances for operator injury will lead to maximizing each operator’s efficiency. Maximized efficiency for a part or process will also improve part throughput, alleviating the potential for a manual drilling process to bottleneck the entire production line.

Understanding Your Material Options

Being that drill guides are utilized with a manual drilling process, it is best to utilize common consumer plastics like ASA and ABS. The lower cost of material for the tool makes it more readily replaced as the tool begins to wear over time. By 3D printing your drill guides, you’ll have a custom piece, designed specifically for your application – maximizing efficiency and making the drill guide safer for your operator.

To learn more about your 3D printing options, reach out to our team by phone at 949.474.9222 or by email at [email protected]. If you’d like to receive a quote for your project, please use our online file upload system.

Related Articles You May Enjoy:

- 3D Printing Tooling: Weldment Fixtures

- 3D Printing Tooling: Inspection Go/No-Go Gauges

- 3D Printing Tooling: Hardware Assembly Templates

Meet Alex Goldsberry

Meet Alex Goldsberry

As a Sales Engineer for Purple Porcupine, Alex focuses on bringing value to customers through his knowledge of additive manufacturing, engineering, and 3D printing technology. Out of the office, Alex enjoys reading investment articles and analyzing stock trends. If you haven’t had a chance to meet Alex yet, stop by our office and say hi or connect with him on LinkedIn!