The New ABS-CF10

ABS-CF10 is an ABS-based material, with 10% chopped carbon fiber, making it 50% stronger and 15% stiffer than standard ABS. It was specifically formulated for use on the Stratasys F123 Series, for the production of durable jigs & fixtures.

The material leverages a soluble support, allowing for design freedom and complex model geometries. Plus, you can create large parts with confidence, knowing that the material’s accuracy is up to 0.2mm.

What It Means For The F123 Series

ABS-CF10 is exclusively available on the F170, F270, and F370. The addition of a high stiffness-to-weight ratio and low moisture-sensitive material enhances the line’s robust offering. Now, more than ever, the F123 Series 3D printers give designers, engineers, and educators access to affordable industrial-grade 3D printing. With the investment of a Stratasys F123 Series printer, a user has access to a wide array of durable FDM thermoplastic materials.

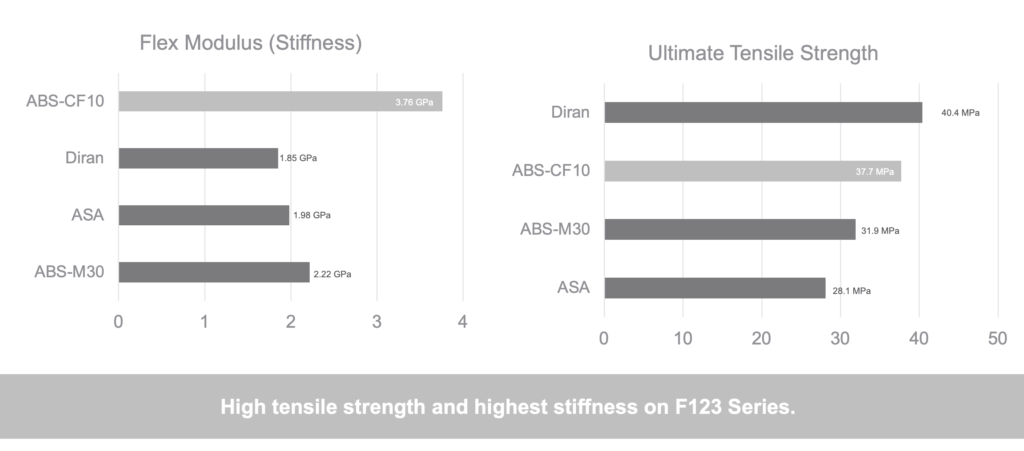

How does it compare to other materials on the F123 Series?

Potential Applications

The unique stiffness and strength allows ABS-CF10 to replace metal components in:

- Functional Prototypes

- Tooling Applications

- Production Parts

Take, for example, the alignment fixture part featured here. The part weighs 50% less than its aluminum counterpart. Lighter tools mean better ergonomics for workers and less power needed to move robotic end effectors.

Take, for example, the alignment fixture part featured here. The part weighs 50% less than its aluminum counterpart. Lighter tools mean better ergonomics for workers and less power needed to move robotic end effectors.

Besides alignment fixture parts, the material is ideal for models that require strength, stiffness, or light weighting. By printing parts in-house using ABS-CF10, you can reduce the lead time to replace machined jigs & fixtures, create models for functional testing, and produce lightweight factory aids.

If you’re interested in learning more about ABS-CF10, reach out to our team by email at [email protected] or by phone at 949.474.9222.