Purple Porcupine provides companies with the tools and knowledge needed to bring their ideas to life; one of those tools being DLP (Digital Light Processing) 3D printing. DLP enables the mass production of end-use parts that are functionally and aesthetically ready for end use. The process uses a projector to flash an image on resin which then cures into a thin layer. This process repeats until the model is complete.

These models achieve industry-leading detail, consistency, and mechanical properties. With our Origin One, we’ve helped customers create strong end-use parts. But that’s not all… get quick turnaround times and high throughput for your parts, without the expensive tooling costs. Origin One is ideal for a plethora of markets such as industrial, automotive, consumer goods, and even medical. We are excited to be able to provide DLP 3D printing to accelerate your design and manufacturing process.

Explore Our Materials

LOCTITE IND402

Black

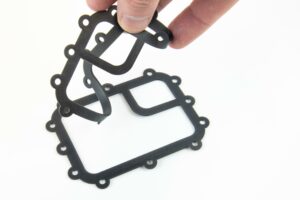

This rubber-like material has high elongation and resilience which allows for sturdy and reliable parts. IND402 is ideal for consumer products and sportswear lattice structures within automotive or consumer goods markets.

LOCTITE 3172

Gray

This tough and durable photopolymer resin, similar to Polypropylene, produces parts with superior impact strength, and a smooth surface finish. LOCTITE 3172 is ideal for manufacturing aids, jigs and fixtures, housings, and insoles within automotive, industrial, and consumer goods markets.

LOCTITE Dura56

Black

A tough and high-impact strength material, Dura56 has an excellent surface finish with a low cost per part, making it a great option for production parts. This material is ideal for enclosures, jigs and fixtures, and functional testing within industrial, automotive and consumer goods markets.

LOCTITE IND3843

Black, Clear, White

IND3843 is a semi-flexible photoplastic resin with exceptional surface finish and good impact resistance. This tough material has a moderate heat resistance, HDT60 (Heat Deflection Temperature of 60°C), and is optimal for a variety of tooling applications. IND3843 is ideal for manufacturing aids, jigs/fixtures, and housings/covers within industrial, automotive, and consumer goods markets.

Somos QuickGen 500

Clear

This DLP resin has a print speed 2x faster than comparable materials. Not only does it print quickly, but it prints accurately. Somos QuickGen 500 is the best option for prototyping because of its balance of flexibility and stiffness. This material is ideal for general and functional prototypes, semi-flexible and detailed applications, and fluid flow analysis within a wide range of markets.

LOCTITE MED413

Clear, White

MED413 is the material for impact resistant medical models or device applications because of its combined stiffness and toughness. This material is capable of meeting ISO 10993-5 and ISO 10993-10 standards for biocompatibility and for finished parts that can function at body temperature. Its quality surface finish and machinability make MED413 useful for practical medical models. MED413 is ideal for medical devices, hearing aids, and medical equipment components within the healthcare industry.

How Customers Are Using DLP

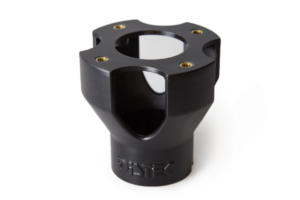

Ghost Robotics produces four-legged autonomous robots that can operate in almost any environment. To maintain production and quality of these robots, Ghost Robotics needed a better way to make lightweight and durable parts with a high-quality surface finish in an efficient way. Their solution? LOCTITE 3172 and LOCTITE 3843. These materials have all the mechanical and aesthetic components that they were looking for to make their robots.

They immediately switched from CNC milling to 3D printing, saving time and money on producing and shipping their parts out. Ghost Robotics was thrilled with what LOCTITE 3172 and LOCTITE 3843 was able to provide for them. Click here to read the full case study.

To receive a free instant quote, click here. To learn more about the Origin One and its materials, email us at [email protected] or give us a call at 949.474.7222.

Meet Katie Elhardt

Meet our Marketing Assistant, Katie Elhardt. Katie is responsible for helping maintain the company website, social media, and events. Her favorite part about Purple is the innovative technology and the company culture.

Outside of work, Katie enjoys attending 80’s concerts, going to Disneyland, and taking long walks near the beach. If you haven’t had the chance to meet her yet, stop by our office or connect on LinkedIn!