ExOne 3D Printers

FFF & BINDER JETTING

Print functional metal parts with the Metal Designlab and Innovent+ from ExOne. With over 20 years of experience, ExOne has long been the global leader in industrial metal 3D printing systems. From aerospace and automotive to energy and defense, companies in a wide array of industries have been leveraging ExOne’s 3D printers.

Explore The Machines

See The Materials

ExOne’s metal 3D printers quickly and sustainably transform more than 10 single-alloy metals – from 17-4PH and 316L to Inconel 718, M2 Tool Steel, and more – into high-density parts. With part quality as good as metal injection molding and better than investment castings, you can create durable models.

Read The Case Studies

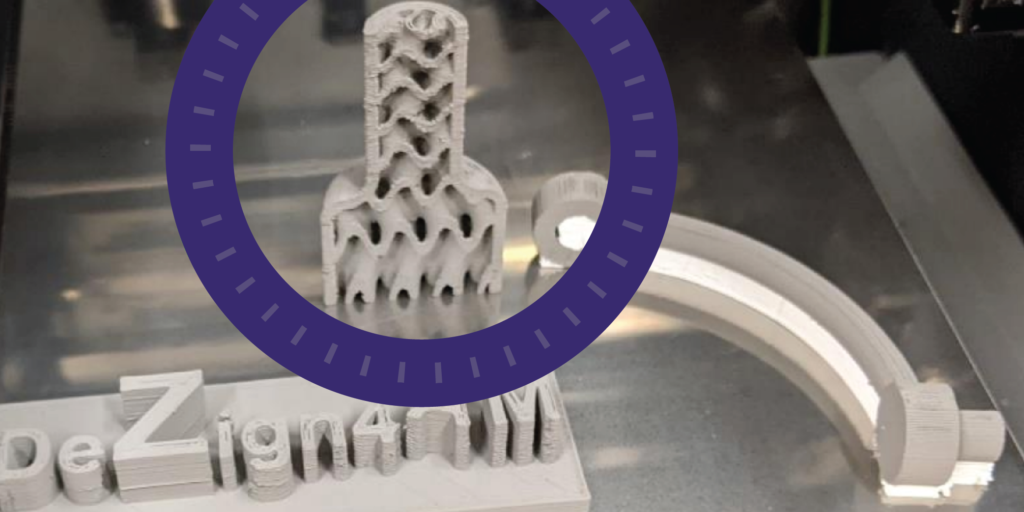

Metal Designlab | University of British Columbia

“[Metal Designlab is] super easy to use, especially for an environment like ours, in an educational environment. We don’t have messy chemicals… It goes directly from the printer to the furnace. That is something I love about this machine. The learning curve is just a few hours for somebody already familiar with plastic printing.”

– Ahmad Mohammadpanah, Dept. of Mechanical Engineering

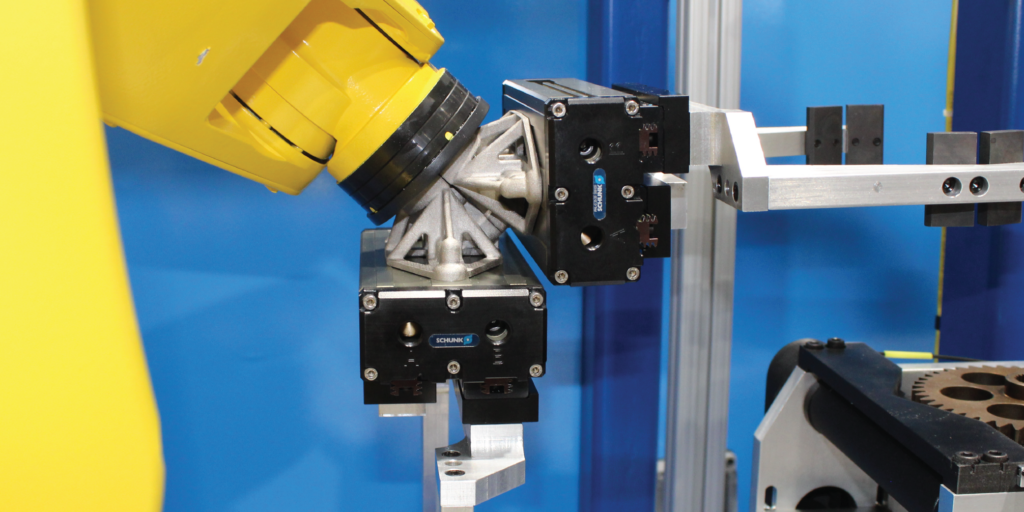

Innovent+ | FreeFORM Technologies

“Binder jetting was the only way to go for this project. It was one-forth the cost of DMLS, and we did it in a strong material that reduced the payload on the robot… The surface quality is superior to any of the other printers. It’s an easy machine to run. It was great for this kind of application.”

– Chris Aiello, VP of Business Development

ExOne 3D Printers

FFF & BINDER JETTING

Print functional metal parts with the Metal Designlab and Innovent+ from ExOne. With over 20 years of experience, ExOne has long been the global leader in industrial metal 3D printing systems. From aerospace and automotive to energy and defense, companies in a wide array of industries have been leveraging ExOne’s 3D printers.

Explore The Machines

See The Materials

ExOne’s metal 3D printers quickly and sustainably transform more than 10 single-alloy metals – from 17-4PH and 316L to Inconel 718, M2 Tool Steel, and more – into high-density parts. With part quality as good as metal injection molding and better than investment castings, you can create durable models.

Read The Case Studies

Metal Designlab | University of British Columbia

“[Metal Designlab is] super easy to use, especially for an environment like ours, in an educational environment. We don’t have messy chemicals… It goes directly from the printer to the furnace. That is something I love about this machine. The learning curve is just a few hours for somebody already familiar with plastic printing.”

– Ahmad Mohammadpanah, Dept. of Mechanical Engineering

Innovent+ | FreeFORM Technologies

“Binder jetting was the only way to go for this project. It was one-forth the cost of DMLS, and we did it in a strong material that reduced the payload on the robot… The surface quality is superior to any of the other printers. It’s an easy machine to run. It was great for this kind of application.”

– Chris Aiello, VP of Business Development

ExOne 3D Printers

FFF & BINDER JETTING

Print functional metal parts with the Metal Designlab and Innovent+ from ExOne. With over 20 years of experience, ExOne has long been the global leader in industrial metal 3D printing systems. From aerospace and automotive to energy and defense, companies in a wide array of industries have been leveraging ExOne’s 3D printers.

Innovent+

Functional metal, ceramic, & composite parts with binder jetting.

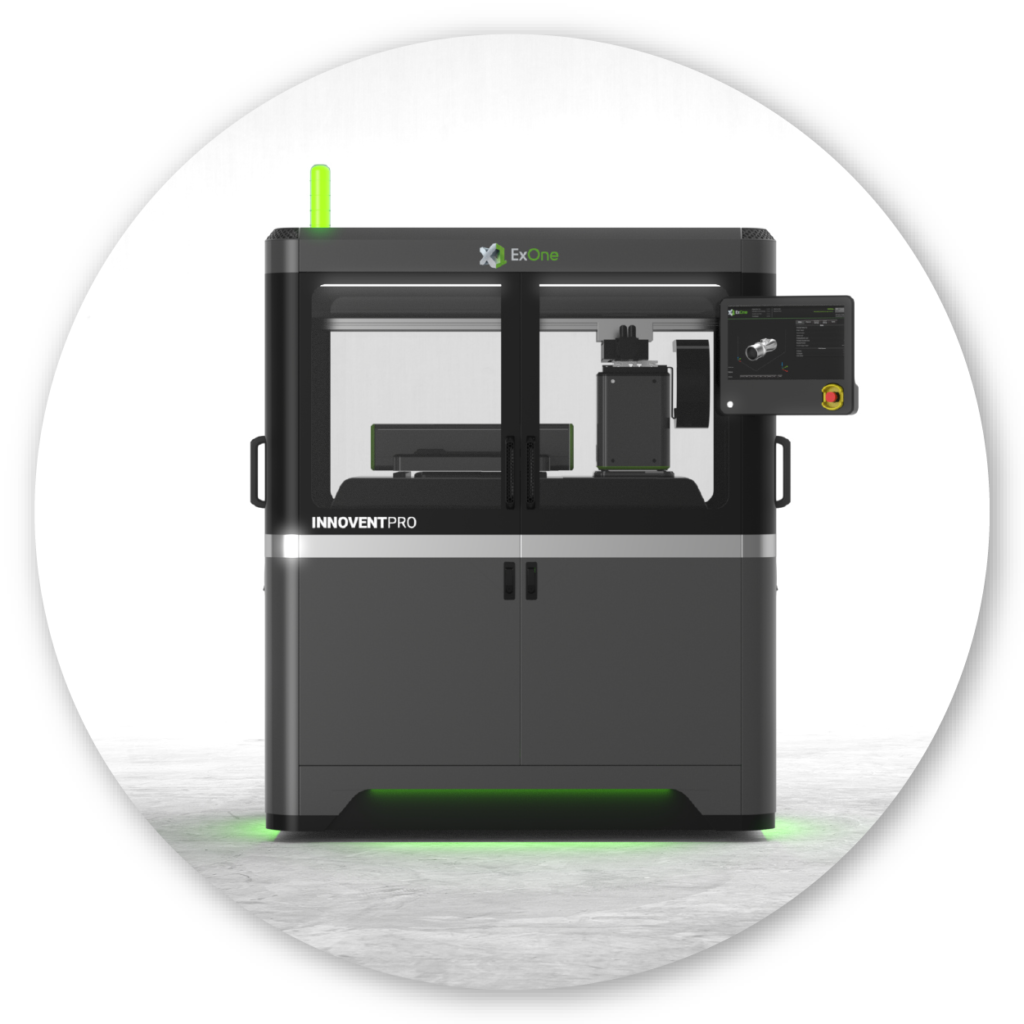

Innovent Pro

Coming Soon

X1F Sintering Furnace

Optimized for Designlab and Innovent+.

See The Materials

ExOne’s metal 3D printers quickly and sustainably transform more than 10 single-alloy metals – from 17-4PH and 316L to Inconel 718, M2 Tool Steel, and more – into high-density parts. With part quality as good as metal injection molding and better than investment castings, you can create durable models.

Read The Case Studies

Metal Designlab | University of British Columbia

“[Metal Designlab is] super easy to use, especially for an environment like ours, in an educational environment. We don’t have messy chemicals… It goes directly from the printer to the furnace. That is something I love about this machine. The learning curve is just a few hours for somebody already familiar with plastic printing.”

– Ahmad Mohammadpanah, Dept. of Mechanical Engineering

Innovent+ | FreeFORM Technologies

“Binder jetting was the only way to go for this project. It was one-forth the cost of DMLS, and we did it in a strong material that reduced the payload on the robot… The surface quality is superior to any of the other printers. It’s an easy machine to run. It was great for this kind of application.”

– Chris Aiello, VP of Business Development