Neo SLA 3D Printers

OPEN SOURCE STEREOLITHOGRAPHY

Build prototypes, rapid tooling, and master patterns with the state-of-the-art Neo stereolithography range. The reliable and proven Neo builds high-quality parts with superior surface quality, accuracy, and detail.

Explore The Applications

Versatile & Efficient 3D Printing

Designed & engineered for industrial-grade performance, the Neo stereolithography 3D printers deliver high-quality prints, time after time.

Reduce Finishing Time By Up To 50%

The Stratasys Neo series produce highly accurate parts with unparalleled industry quality. The machines have exceptional layer-to-layer alignment repeatability, and the printed parts are dimensionally accurate, with exceptional sidewalls and crisp feature resolution.

Proven Reliability & Quality Assurance

Carefully engineered for throughput, the Neo series use state-of-the-art technology, proven components, and aesthetic finishes.

Open Resin System

As an open resin system, users can print with any commercially available 355 nm hybrid resin.

Fast Build Speeds

Build speeds are enhanced with carefully developed and efficient software. Plus, dynamic beam shape control is standard throughout the Neo range, with a variable option available for even greater build speeds.

Request A Quote

Explore The Machines

Why choose Stratasys Neo stereolithography 3D printers? Check out the spec sheet to learn more.

Neo800

Platform Size: 31.5 x 31.5 x 23.6” (800 x 800 x 600 mm)

Laser: 2 Watt

Beam Size & Focus: 150 to 600 μm (Dynamic & Variable)

Build Modes: HD & SD

Neo450s

Platform Size: 17.72 x 17.72 x 15.75” (450 x 450 x 400 mm)

Laser: 2 Watt

Beam Size & Focus: 80 to 750 μm (Dynamic & Variable)

Build Modes: HD & SD

Neo450e

Platform Size: 17.72 x 17.72 x 15.75” (450 x 450 x 400 mm)

Laser: 1 Watt

Beam Size & Focus: 250 μm (Dynamic & Variable)

Build Modes: SD

Explore The Case Study

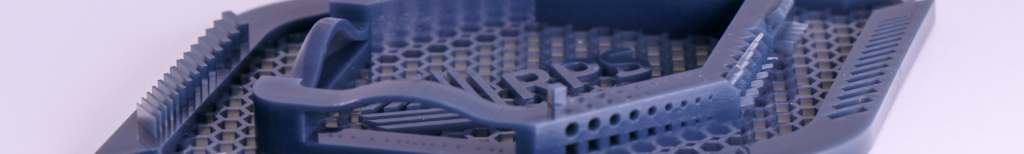

Prototype Parts For BAC Mono R Supercar

“3D printing was crucial for keeping design-to-manufacture times down and allowing us to meet tight deadlines with ample creative freedom – while the quality of the finished result is testament to the work of the Neo800.”

– Ian Briggs, BAC Design Director

BAC needed large 3D printed parts for the Mono R prototype. The Stratasys Neo800, one of the largest 3D printing stereolithography systems available, was chosen to produce the prototype parts.

3D printing offered BAC significant advantages, including: freedom to produce prototype parts with sinuous, organic designs, and weight savings impossible with traditional methods of manufacturing.