The beauty of housing the largest and most advanced fleet of Stratasys machines on the West Coast is that the possibilities are endless. From intricate medical models to functional composite tooling, we’ve seen and printed it all. But every once in a while, the opportunity arises to do a simple internal project and we just can’t help ourselves. Especially recently, when we decided a little something extra was needed to complement some purple sports coats. Our solution – 3D printed lapel pins printed on the Stratasys J750 PolyJet printer.

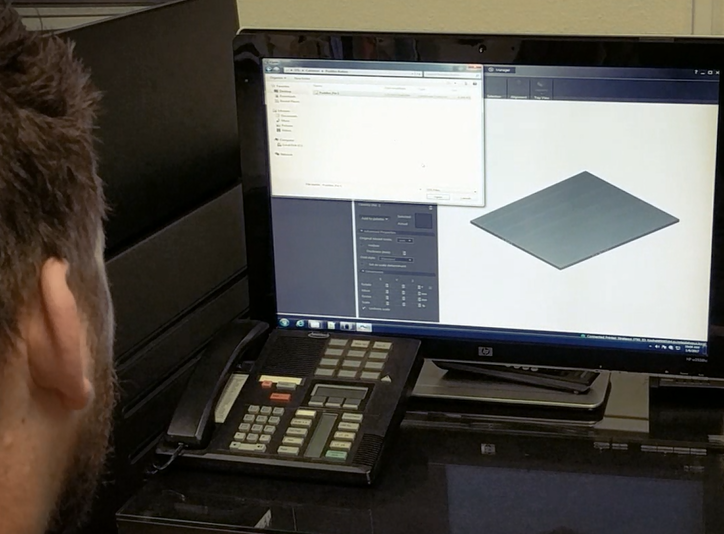

We decided Puddles the platypus would look superb on a lapel and with that, trustee application engineer, Cameron Williams, began working on a design. Once the design concept was finalized, the STL file was processed using PolyJet Studio, allowing us to manipulate the file’s orientation, print geometry, as well as build surface. The file was then sent to our J750 that went to work, jetting and instantly curing tiny droplets of liquid photopolymer layer by layer with UV light.

Hot off the press, the parts were ready for the first step of post-processing; removing as much of the support material as possible. After the larger pieces of support had been taken off, the pins were transferred to a high-pressured water jet where any remaining support material was washed away. Once the parts were completely clean, coat pins were then glued to their back sides, officially confirming lapel pin status.

With the pins nearing completion, a metallic coat was then applied to give them a bright luster. Later, after the first coat had dried, multiple patina coats were applied to enhance the details of the pins. To achieve a more aged metal look, a clean brush was then used to remove the last patina coat, only allowing enough to remain in the pins’ crevasses. With a few hours of drying time, the customized Platypus lapel pins were completed and ready to wear.

Printing the lapel pins was a swift task proving the ease-of-use and desirability of Stratasys 3D printing technology. Whether you’re in need of something as complex as a mechanical model or as simple as a fashion accessory, you can always find a solution with 3D printing. If you’re interested in discussing how to implement these advanced 3D technologies into your project, give us a call or contact us at [email protected].