FDM THERMOPLASTICS

ASA

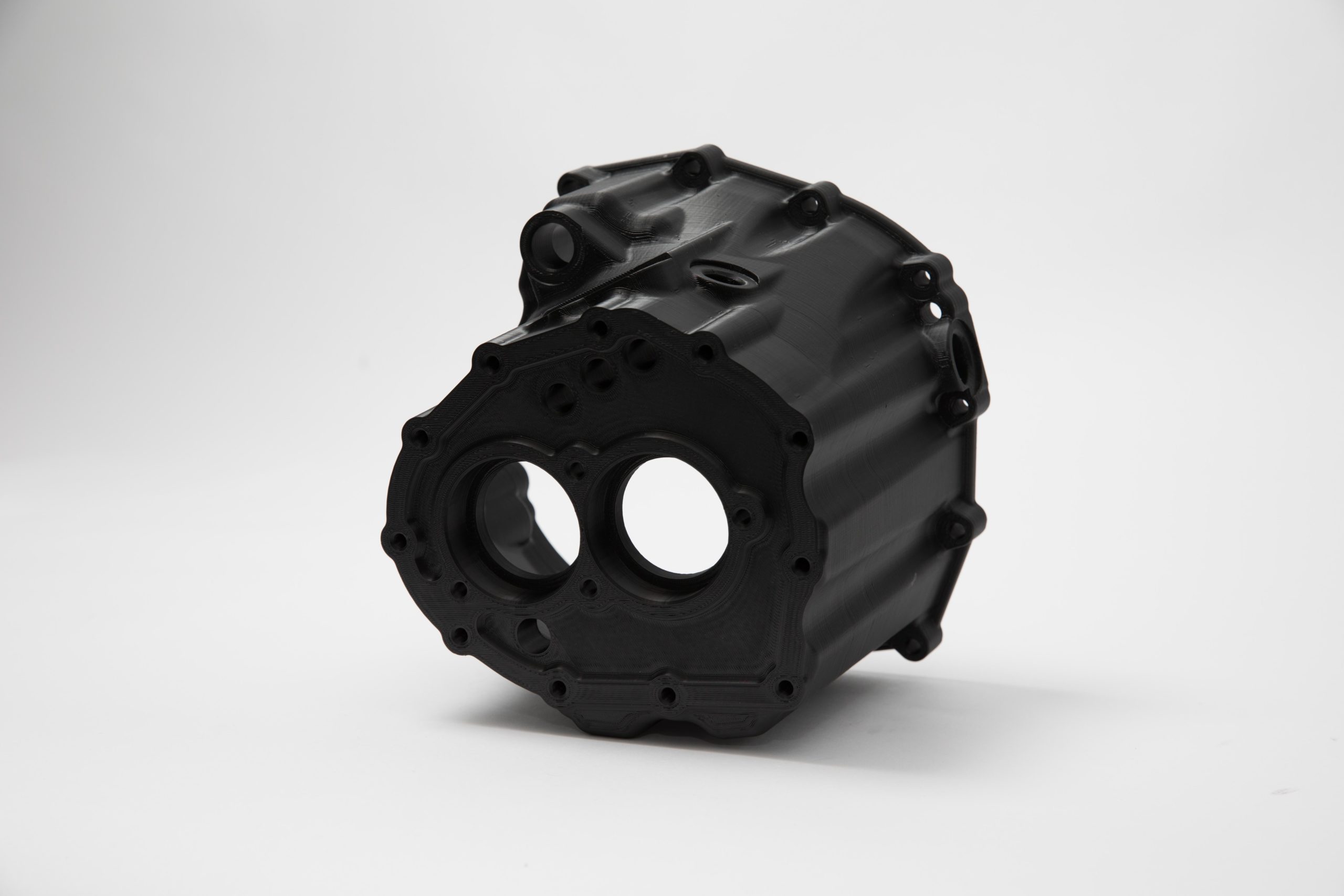

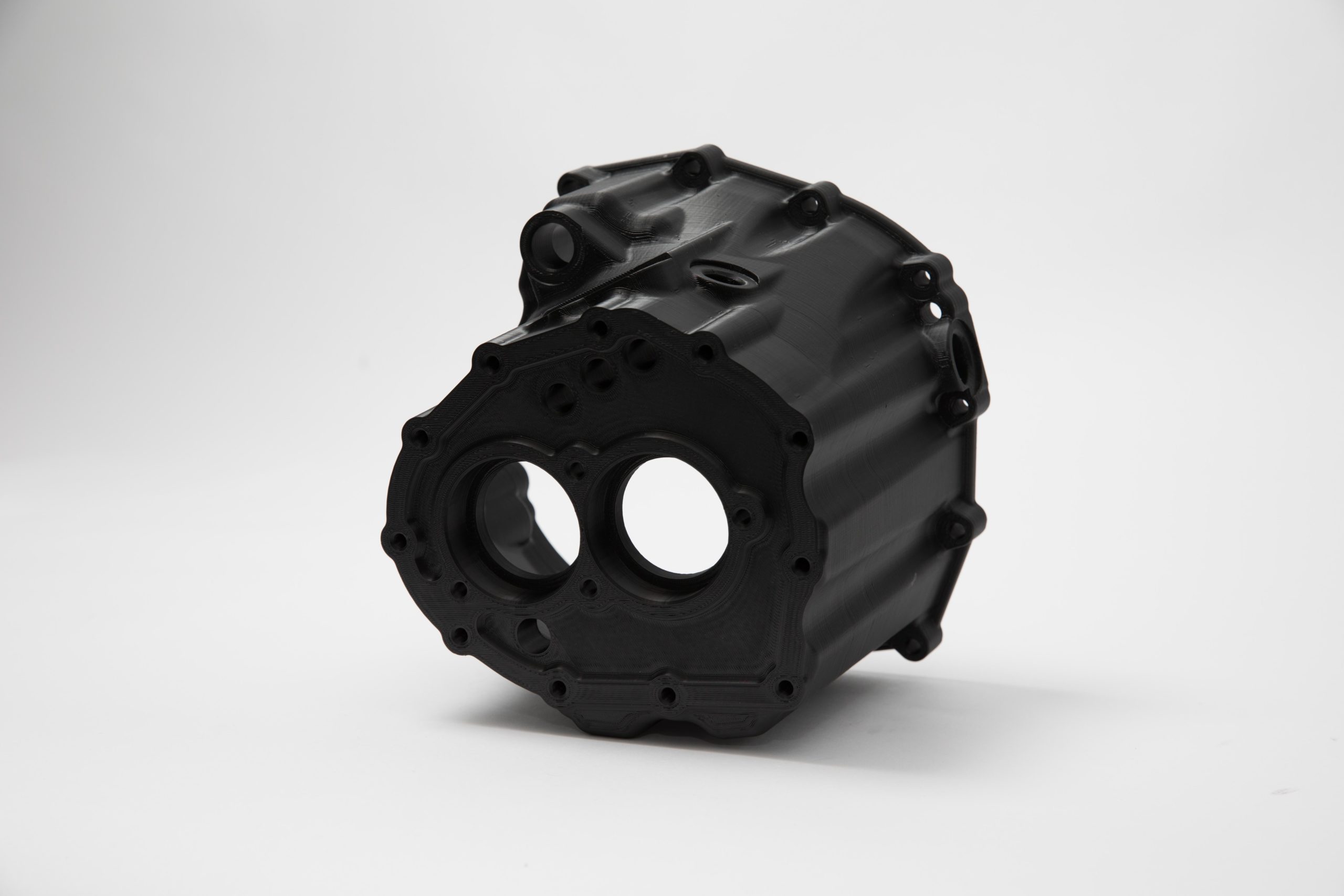

ASA (Acrylic Styrene Acrylonitrile) material can help you build high quality parts, with exceptional UV stability, and the best aesthetics of any FDM thermoplastic.

See The Specs

ASA’s wide array of capabilities, including its expansive machine compatibility, allows the material to be used in many circumstances. ASA combines UV-resistance with the best part aesthetics FDM 3D printing has to offer. Its durability makes it well suited for outdoor, commercial, and infrastructure use. And, its sleek matte finish, makes it ideal for prototyping.

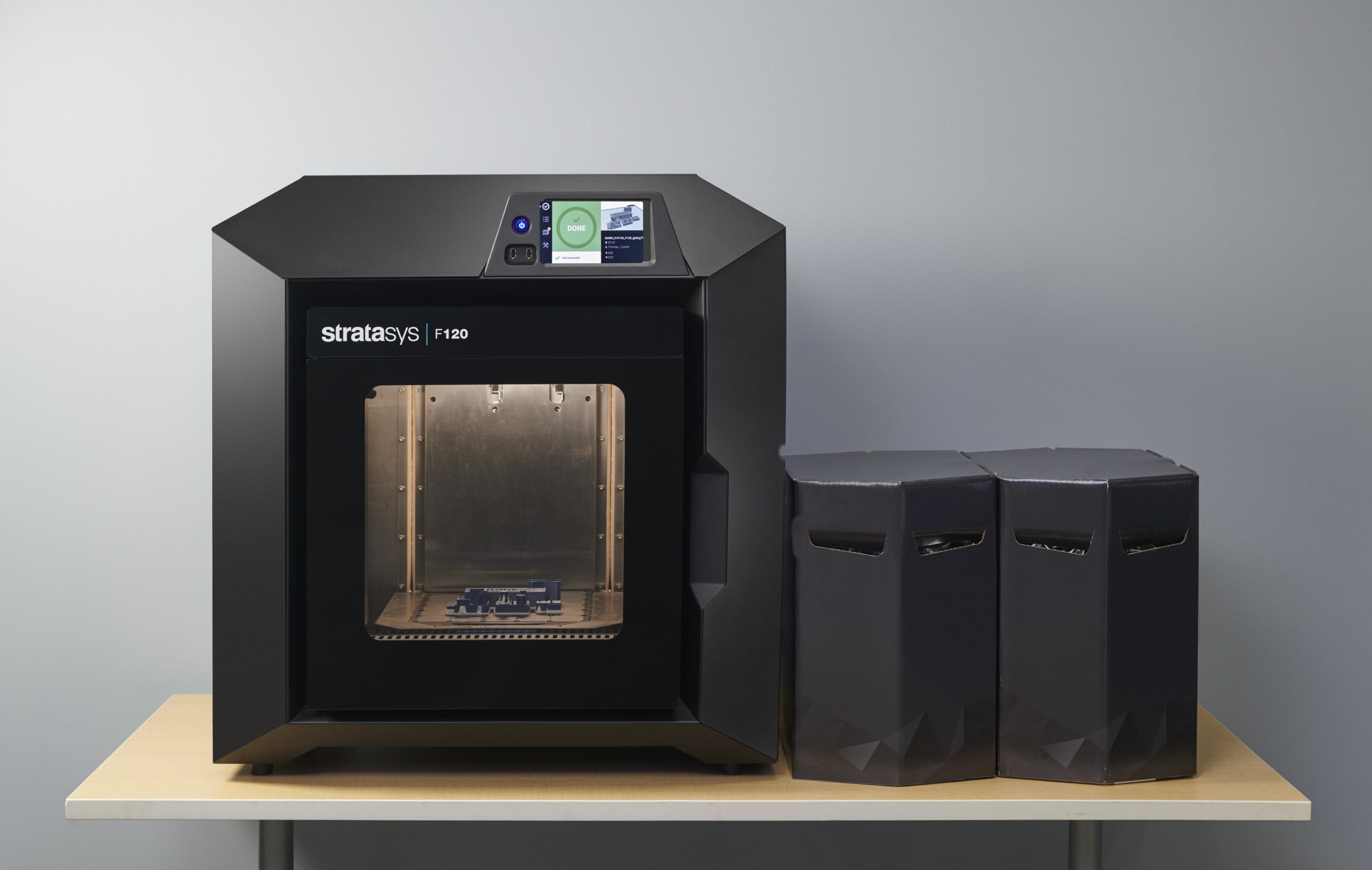

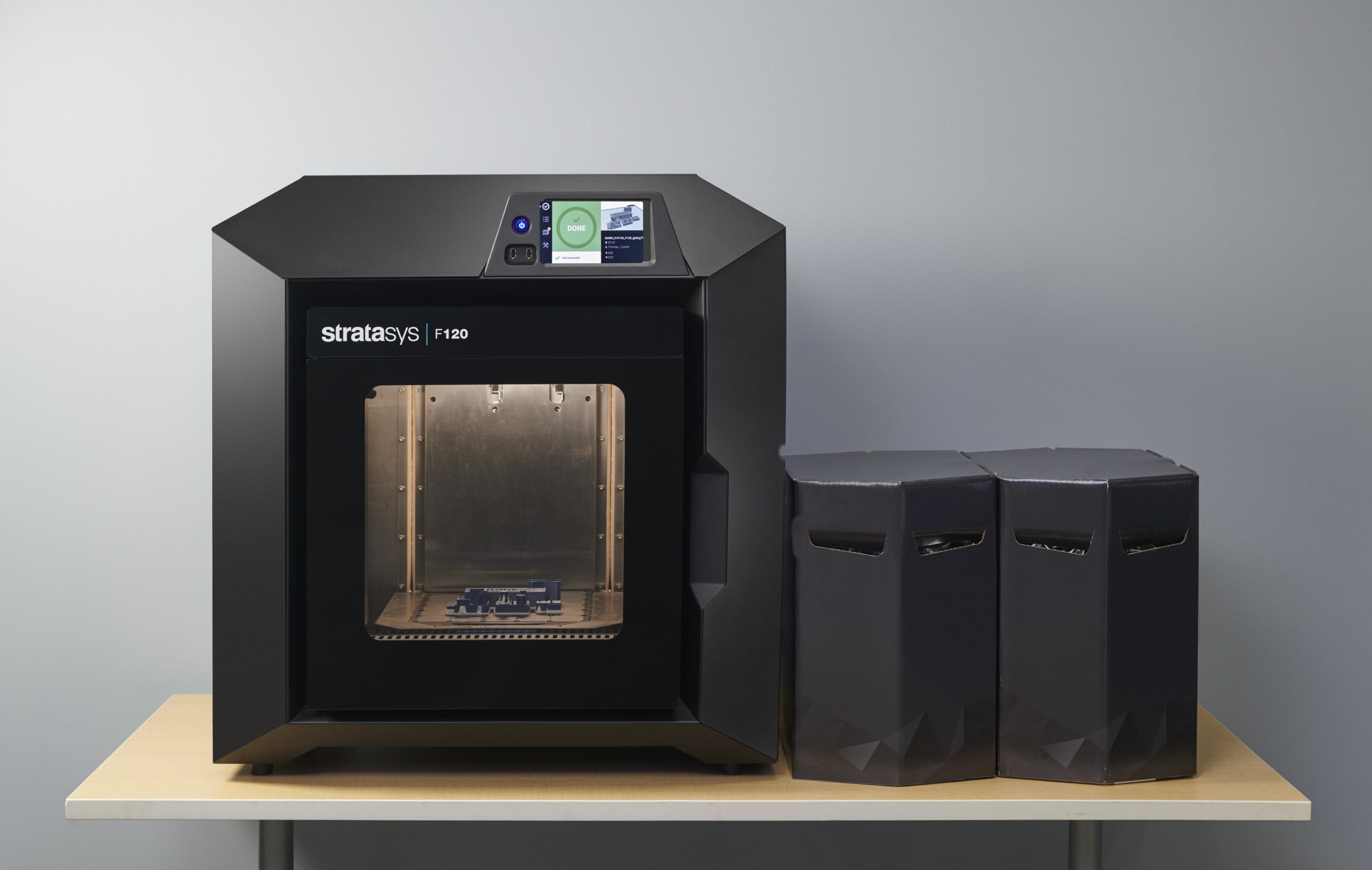

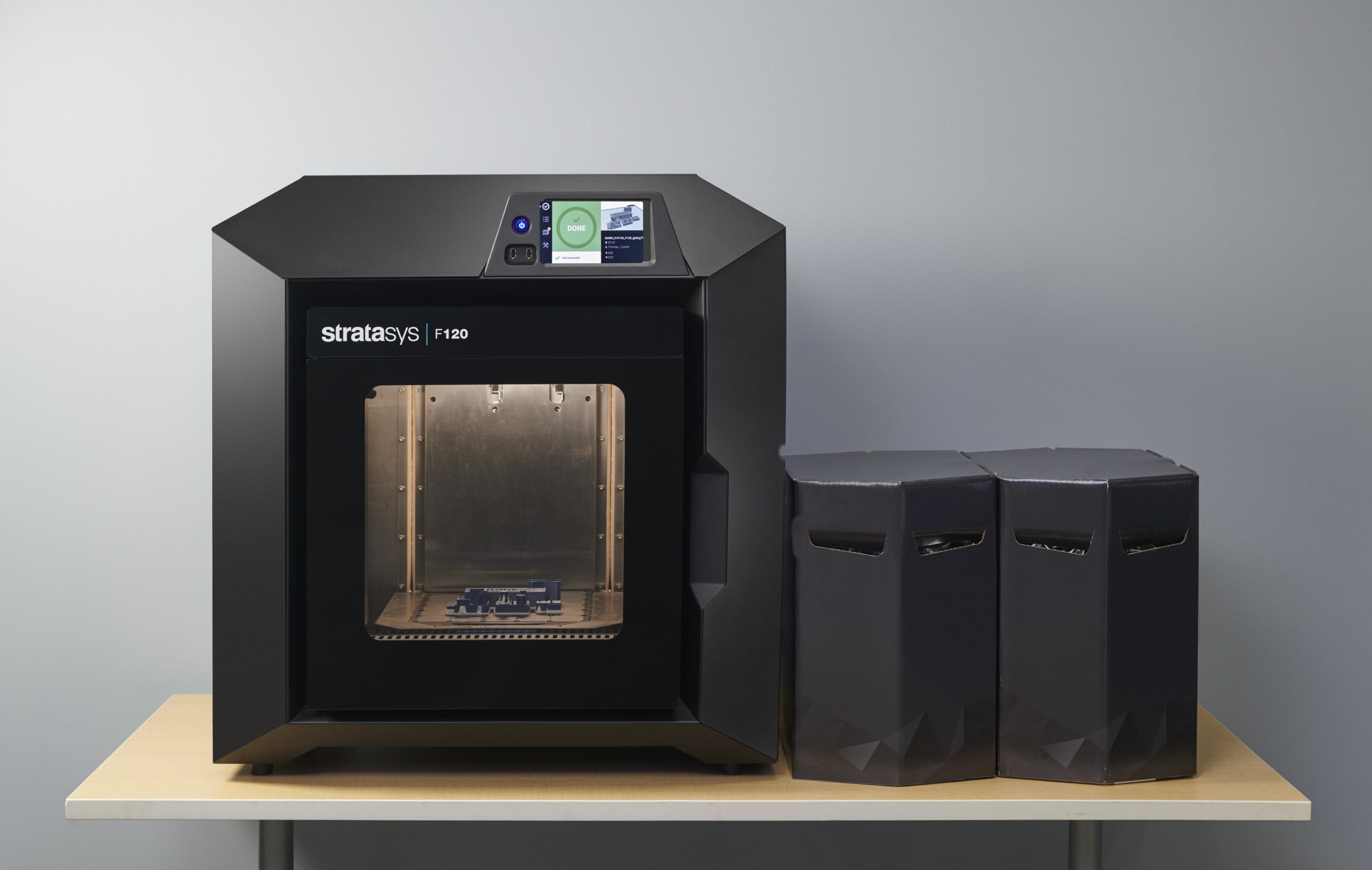

Machine Availability: F120, F170, F270, F370, F770, Fortus 450mc, F900

Layer Height: 0.020 in., 0.013 in., 0.010 in., 0.007 in., 0.005 in.

Color Options: Ivory, Black, Dark Gray, Light Gray, White, Red, Orange, Yellow, Green, Dark Blue

Request A Quote

Prototype Smarter

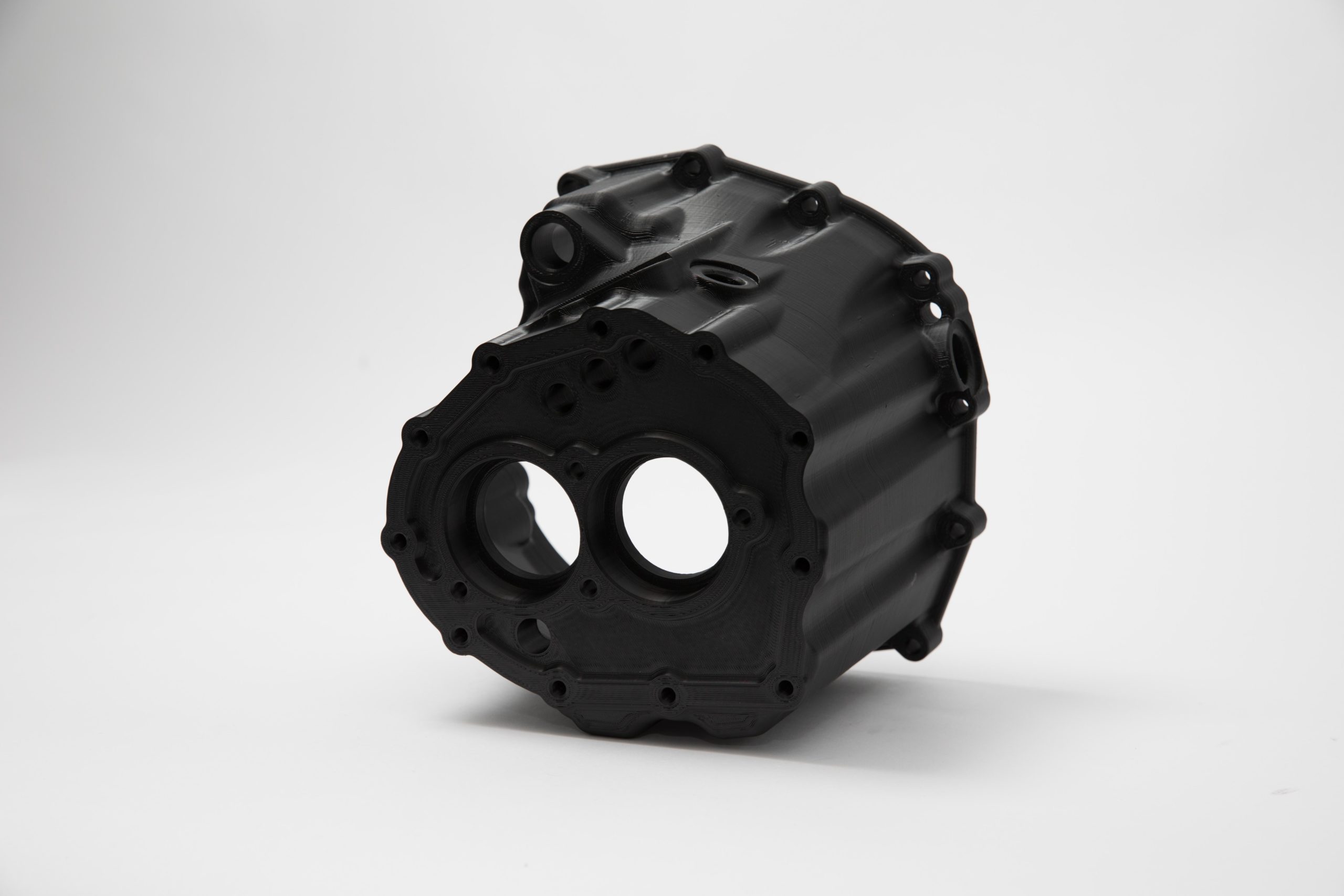

Boom Supersonic, a passenger supersonic transport company, used ASA to develop a working prototype of a rudder limiter.

Boom Supersonic needed a functional prototype, quickly. Using traditional methods, this process would take about eight weeks and have a high material cost. Instead of machining a prototype, Boom used additive manufacturing to make the individual parts with ASA. This saved them 86% with lead time and 96% in material costs. With ASA’s strength Boom was able to make a working prototype fast, and feel safe with the product.

This is only one case where ASA helped a company develop a product. There are unlimited possibilities with a material so versatile. To learn more about the 3D printing material options for your project, contact our team.

FDM THERMOPLASTICS

ASA

ASA (Acrylic Styrene Acrylonitrile) material can help you build high quality parts, with exceptional UV stability, and the best aesthetics of any FDM thermoplastic.

See The Specs

ASA’s wide array of capabilities, including its expansive machine compatibility, allows the material to be used in many circumstances. ASA combines UV-resistance with the best part aesthetics FDM 3D printing has to offer. Its durability makes it well suited for outdoor, commercial, and infrastructure use. And, its sleek matte finish, makes it ideal for prototyping.

Machine Availability: F120, F170, F270, F370, F770, Fortus 450mc, F900

Layer Height: 0.020 in., 0.013 in., 0.010 in., 0.007 in., 0.005 in.

Color Options: Ivory, Black, Dark Gray, Light Gray, White, Red, Orange, Yellow, Green, Dark Blue

Request A Quote

Prototype Smarter

Boom Supersonic, a passenger supersonic transport company, used ASA to develop a working prototype of a rudder limiter.

Boom Supersonic needed a functional prototype, quickly. Using traditional methods, this process would take about eight weeks and have a high material cost. Instead of machining a prototype, Boom used additive manufacturing to make the individual parts with ASA. This saved them 86% with lead time and 96% in material costs. With ASA’s strength Boom was able to make a working prototype fast, and feel safe with the product.

This is only one case where ASA helped a company develop a product. There are unlimited possibilities with a material so versatile. To learn more about the 3D printing material options for your project, contact our team.

FDM THERMOPLASTICS

ASA

ASA (Acrylic Styrene Acrylonitrile) material can help you build high quality parts, with exceptional UV stability, and the best aesthetics of any FDM thermoplastic.

Request A Quote

See The Specs

ASA’s wide array of capabilities, including its expansive machine compatibility, allows the material to be used in many circumstances. ASA combines UV-resistance with the best part aesthetics FDM 3D printing has to offer. Its durability makes it well suited for outdoor, commercial, and infrastructure use. And, its sleek matte finish, makes it ideal for prototyping.

Machine Availability: F120, F170, F270, F370, F770, Fortus 450mc, F900

Layer Height: 0.020 in., 0.013 in., 0.010 in., 0.007 in., 0.005 in.

Color Options: Ivory, Black, Dark Gray, Light Gray, White, Red, Orange, Yellow, Green, Dark Blue

Prototype Smarter

Boom Supersonic, a passenger supersonic transport company, used ASA to develop a working prototype of a rudder limiter.

Boom Supersonic needed a functional prototype, quickly. Using traditional methods, this process would take about eight weeks and have a high material cost. Instead of machining a prototype, Boom used additive manufacturing to make the individual parts with ASA. This saved them 86% with lead time and 96% in material costs. With ASA’s strength Boom was able to make a working prototype fast, and feel safe with the product.

This is only one case where ASA helped a company develop a product. There are unlimited possibilities with a material so versatile. To learn more about the 3D printing material options for your project, contact our team.