Background

Ultraviolet and electron beam-curable resins have become common manufacturing materials, used across many industries. This is largely due to the global adoption of additive manufacturing. UV/EB resins can be instantly transformed from liquid to solid state, when thin layers or droplets are exposed to the proper wavelength of light. 3D printing technologies such as Stereolithography (SLA), Digital Light Processing (DLP), and Material Jetting (PolyJet) use these resins to quickly create precise plastic parts with complicated features, without the need for costly injection mold tooling, which can take many weeks to produce. Besides 3D printing, many other large industrial companies use UV/EB resins for a variety of applications, including graphic arts, packaging, dental, medical adhesives, and photoresists.

Finished goods created with SLA, DLP, or PolyJet technologies are safe to handle and, if desired, may be disposed of as common household waste. However, each of these technologies generates waste in the form of unused resin, which is uncured. Waste resin in its liquid state is considered hazardous waste. Companies utilizing these processes must follow strict Environmental Protection Agency (EPA) guidelines when dealing with and handling these waste materials.

Not only are uncured resins bad for the environment and expensive to safely dispose of, but companies that are deemed “large quantity generators” (LQGs) of hazardous waste face increased government and public scrutiny. For this reason, many in the industry are looking for ways to reduce or eliminate the need to dispose of UV/EB byproducts as hazardous waste.

Current Solutions

Until now, there has not been an easy or automated way for companies to process these resins themselves. There are essentially three solutions commonly used today:

- Expose waste resin to sunlight

Unfortunately, only a very thin top layer of resin hardens with this method, so only very thin layers of resin can be processed at a time. This is very time consuming, requires a sunny day, and usually fails to yield a fully cured result. - Pay a hazardous waste company to make scheduled pickups

This method is costly, requires that you house a large collection drum, and can possibly put you on the EPA’s “radar” as an LQG. - Illegally dump the materials

PLEASE NEVER CONSIDER THIS AS AN OPTION!

The WRAP™ Technology Solution

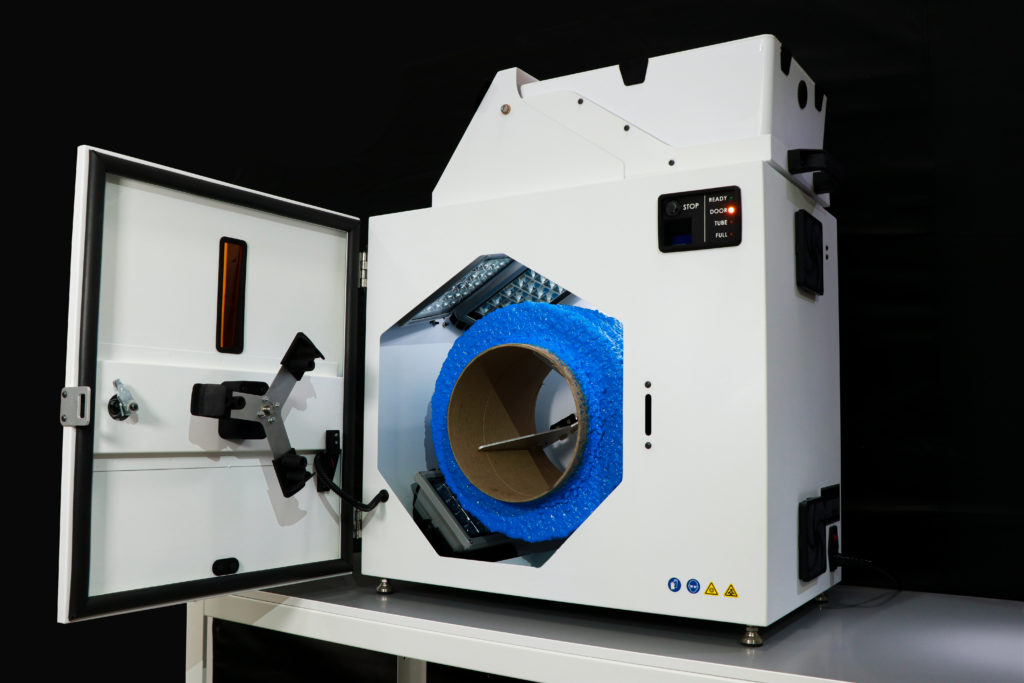

The Onulis W7500 automatically converts UV waste resin into a fully cured solid plastic stock, which can be disposed of as standard household waste. WRAP, the patent pending technology inside, stands for Waste Resin Axial Printing. With WRAP™ technology, you can easily transform hazardous waste resin into disposable plastic stock, avoiding storage and costly disposal.

How It Works

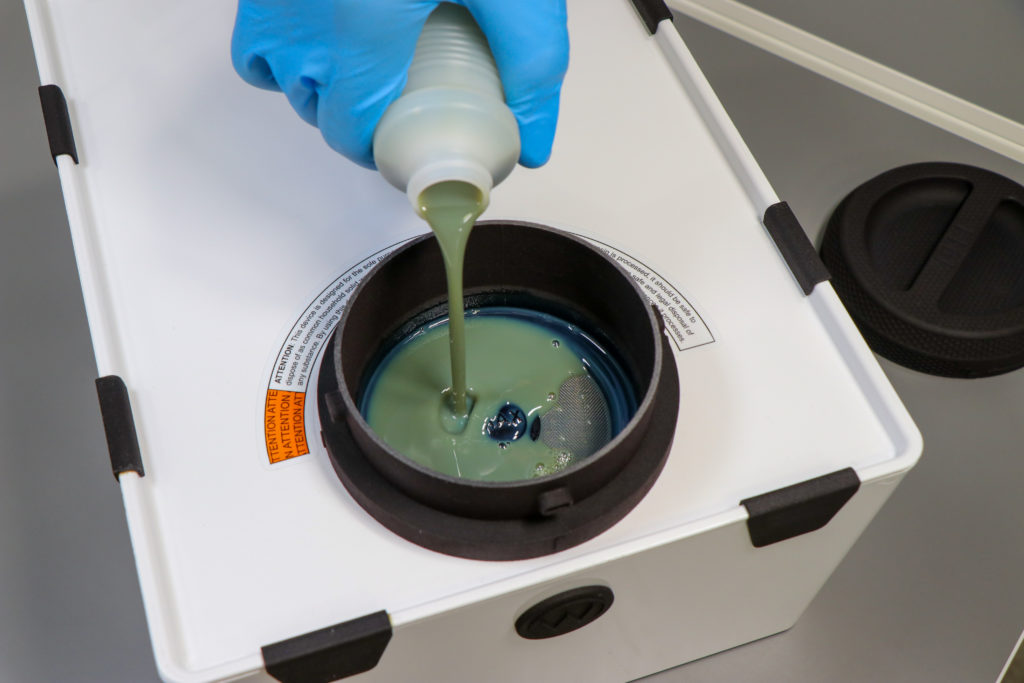

First, waste resin is separated into droplets via the gravity comb. This technique eliminates the need for pumps, tubes, and orifices, which can clog and fail. Next, the droplets freefall through a light corridor which initiates the state change from liquid to solid. The droplets then land on a disposable rotating paper mandrel. The mandrel carries the droplets and exposes them to an intense concentration of UV rays, fully curing each droplet independently. The mandrel is then removed from the W7500 and can be disposed of as common household waste. (Please consult your local municipality before disposing of any material.)

Smarter Disposal of UV Waste

With the Onulis W7500, the first technology-driven solution for handling UV/EB resin waste, you can avoid time-consuming homespun solutions and expensive outsourcing that can draw unwanted oversight.

The machine allows your team to automatically process resin in-house, safely and efficiently.

To learn more about how you can start leveraging WRAP technology, give our team a call at 949.474.9222 or email us at [email protected].

Meet Talena Graham

Meet our Marketing Manager, Talena Graham. Talena is responsible for Purple’s online presence, event & trade show planning, and physical marketing content. Her favorite part about Purple is the broad range of 3D printing applications and the incredible team.

Outside of work, Talena enjoys listening to good (or bad) audiobooks, a good cup of tea, and watching movies. If you haven’t had the chance to meet her yet, stop by our office or connect on LinkedIn!