I have been in the 3D printing industry since 2013. I’ve seen how trends come and go, new technologies promise to be a silver bullet, and how everyone is holding out for the latest and greatest technology. One thing remains consistent: PolyJet and FDM technologies have remained the most prolific and installed 3D printers at industry leading companies.

Here's Five Reasons Why:

Complimentary Technologies

FDM and PolyJet are complementary technologies. FDM provides durable and robust thermoplastic parts that hold up in industrial environments. Some common material examples are ABS, Nylon 12 Carbon Fiber, and ULTEM 9085. PolyJet, a photopolymer resin technology, provides smooth surface finish and highly accurate multi-material parts. Some common material examples are VeroVivid, Digital ABS Plus, and Agilus30.

This combination meets most of the needs in a 3D print lab. With this in mind, I always tell my customers to buy printers with the 80/20 rule in mind: Buy printers that meet 80% of your needs and outsource the rest. For example, large parts or parts that require exotic materials – you’ll have a greater ROI when you invest with this mindset.

Cartridge-Based

FDM and PolyJet 3D printers are the only technologies that are cartridge-based. Most 3D print lab managers do not want to deal with loose powders, open vats, resins, or other hazardous materials. Cartridges eliminate this problem, allowing for easy storage, flexibility for change requests, and versatility.

User-Friendly

PolyJet and FDM 3D printers are very easy to use. Whether you’re purchasing a J55, F370, or Fortus 900, your printers can be setup in an office environment. And you don’t have to be highly-trained to run the machine.

Changing materials, calibration, and job setup is easy. Stratasys GrabCAD Print software is free and anyone can set up a virtual build. The user-friendly software allows 3D print lab managers to schedule jobs and monitor print status.

Plus, when prints are finished, the materials are fully cured, needing limited post-processing. In a matter of hours, your team can have a finished 3D part.

Reliability

Stratasys FDM and PolyJet 3D printers are dependable – 3D print labs rely on them to print high quality parts on a daily basis. In a typical lab, the 3D printer manager will receive files from their engineers throughout the day, planning the print job for overnight. Stratasys machines don’t require constant supervision; simply press print and the parts will be ready the next morning.

Companies rely on Stratasys 3D printers, so they won’t have to spend their time tinkering their printer to get it to perform. Stratasys printers command a premium price because they are engineered to the highest standard. Personally, I have seen PolyJet printers with 40,000 hours on them!

Service, Service, Service

Stratasys invented both FDM and PolyJet technologies. And they support their printers with the most robust 3D printer service organization in the world. If your printer has an issue, Stratasys will send a highly trained technician to fix your printer.

All new printers come with a 1-year warranty (including both parts and labor). Stratasys offers printer maintenance contracts to keep their printers running smoothly for years after installation. With high-quality product standards and dependable customer service, your team will not have to worry about machine downtime.

To learn more about Stratasys’ FDM and PolyJet technologies, please reach out to our team at [email protected] or 949.474.9222.

Meet Gabe Suppes

Meet our Senior Sales Engineer, Gabe Suppes. He assists our customers in adopting the latest technology from Stratasys, eviXscan, ProtoMAX, and Materialise. He has been selling capital equipment for over 10 years, giving him a broad understanding of both additive and subtractive applications.

Out of the office, Gabe enjoys reading, hiking, downhill skiing, mountaineering, trying new restaurants, and travelling. If you haven’t had the chance to meet Gabe, connect with him on LinkedIn!

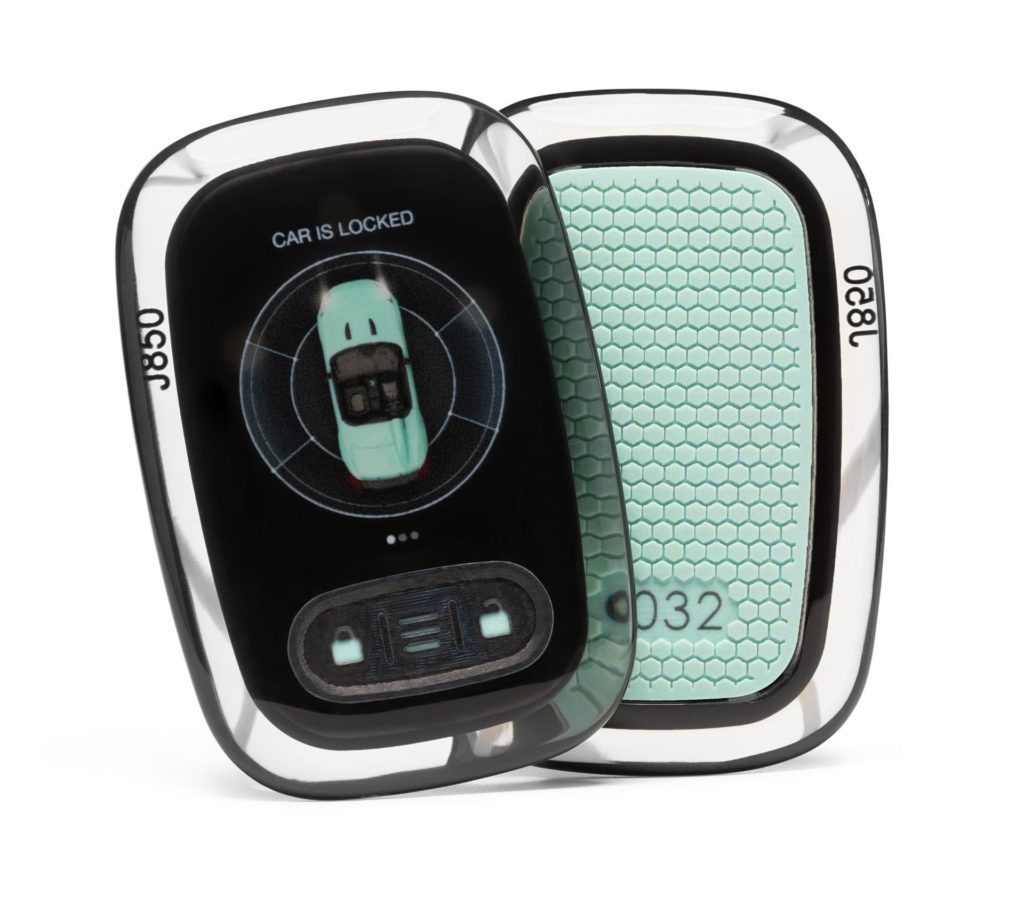

The New J850 Pro: Faster, Easier and Better Without the Color

The J850 has proven to be the designers most valuable tool for quickly getting better color, material, and finish to market faster. Unfortunately, engineers and their companies that have no

End of Arm Tooling with FDM

Robotic devices are typically used as a cost-effective alternative to repetitive and labor-intensive operations when manufacturing, inspecting, packaging, and transporting products. In most cases, robots use end of arm tool

Multi-Material Printing with PolyJet

Creating unique and visually stunning prototypes has never been easier. For simple prototypes, Stratasys PolyJet machines generate detailed and effective models. But with projects requiring multi-body assemblies, full-color options, and