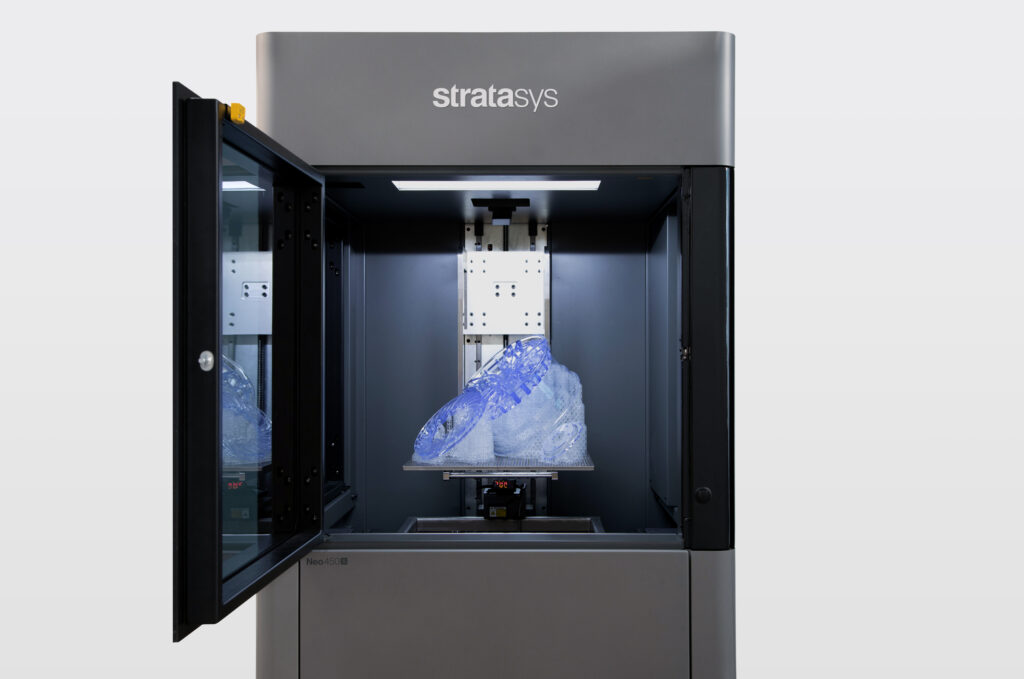

Silverstone Composites, a composite manufacturing solutions provider, needed a fast way to produce mandrel tools for a Formula One racing team. Previously, they were using outdated Stereolithography, which had poor material properties and a long post processing solution that took weeks. Their answer? The Stratasys Neo450s 3D printer.

With the Neo450s, the Silverstone team has been able to produce high temperature, tear resistant parts within a matter of hours. With the open resin system, their team can print many different materials with a variety of properties that fit customers’ specific requirements. Producing mandrel tools normally requires a lot of post processing time but “the surface finish [of the Neo450s] is so good that post processing time is greatly reduced, and there is no need for manual labor, other than lifting the mandrel out of the build tray and transporting it,” says Marcus Trofimov, Founder of Silverstone Composites.

The Neo450s uses dynamic laser beam technology that increases detail, improves accuracy, and maintains low variability. This machine streamlines the manufacturing process and enables Silverstone to ship off their parts soon after they come off the printer. Because of this, customers can request more parts on-demand.

The ability to use an open-source, high-quality Stereolithography 3D printer has transformed Silverstone’s production process and “increases [their] chances of evolving even further as a business.”

Platform Size: 17.72 x 17.72 x 1.97 in. (450 x 450 x 50 mm)

Laser: 2 Watt

Beam Size & Focus: 80 to 750 μm (Dynamic & Variable)

Layer Resolution: 50 to 200 μm

Build Modes: HD & SD

Material Compatibility: Open resin system – compatible with commercially available 355 nm stereolithography resins

Dimensions: 41.3 x 48.2 x 74.8 in. (1050 x 1225 x 1900 mm)

Weight: 1323 lb (600 kg)

To learn more about the Neo450s, give us a call at 949.474.9222 or email us at [email protected].

Meet Katie Elhardt

Meet our Marketing Assistant, Katie Elhardt. Katie is responsible for helping maintain the company website, social media, and events. Her favorite part about Purple is the innovative technology and the company culture.

Outside of work, Katie enjoys attending 80’s concerts, going to Disneyland, and taking long walks near the beach. If you haven’t had the chance to meet her yet, stop by our office or connect on LinkedIn!