Origin One

PRODUCTION QUANTITIES | ROBUST MATERIALS | STRONG, END-USE PARTS

Develop materials, products, and processes — then scale to large quantities. All on the same production-ready platform.

Manufacture The Impossible

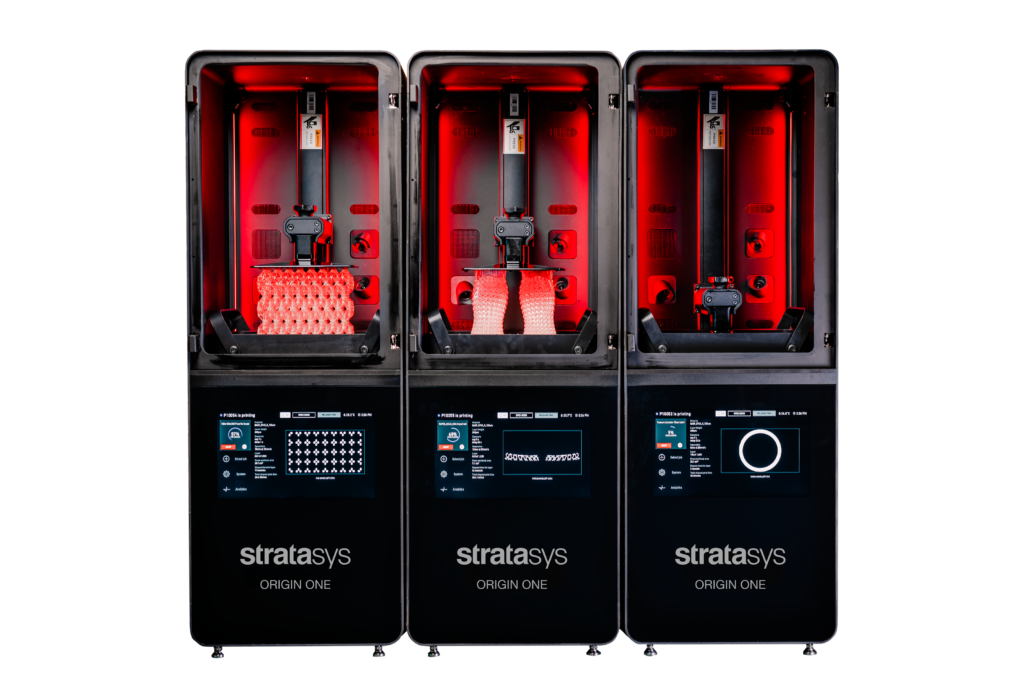

The Stratasys Origin One, manufacturing-grade 3D printer, enables the mass production of end-use parts.

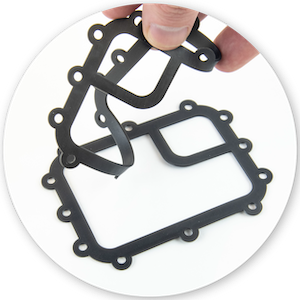

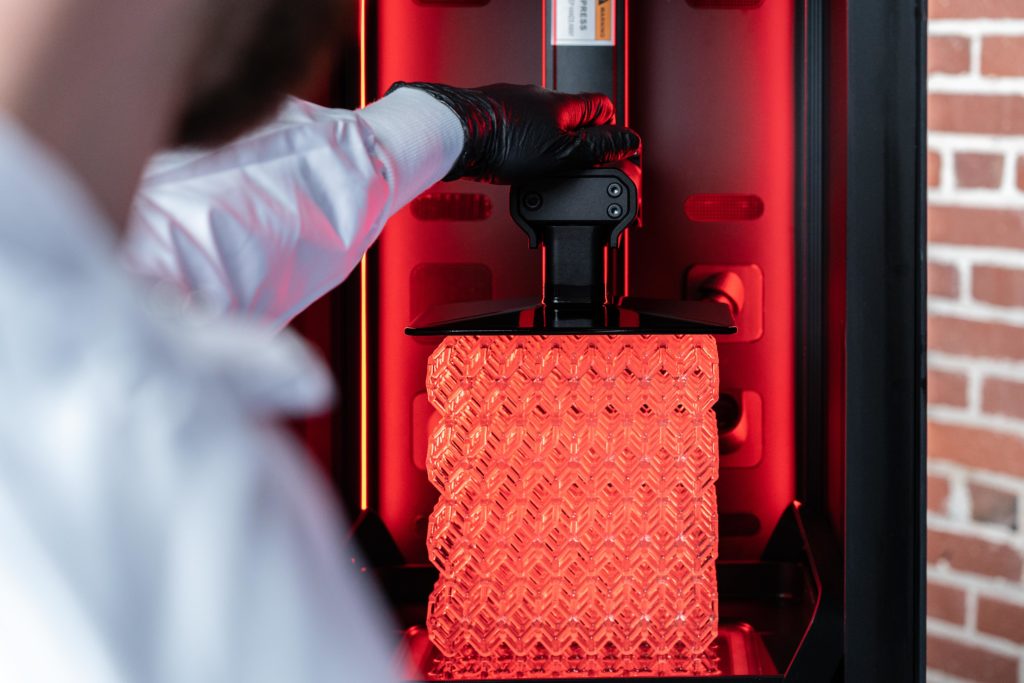

Programmable PhotoPolymerization (P3) technology delivers exceptional accuracy, consistency, and isotropy. Print details less than 50 microns in size, with high-accuracy open-source materials. Material possibilities are constantly expanding – Stratasys is working with leading chemical companies to co-develop innovative photopolymers for a wide variety of applications. The resins are engineered to be easy-to-handle and rapidly post-processed.

Origin One has an optimized build volume, compact footprint, and minimal power requirements. Your team can efficiently maximize your production capacity per square foot.

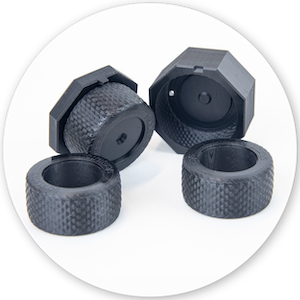

Parts printed on Origin One offer smooth, beautiful surface qualities, without secondary finishing, sanding, or painting. The machine was designed for usability – letting you leverage the expansive capabilities of 3D printing in nearly any setting.

Request A Quote

See The Specs

Build Envelope: 192 x 108 x 370 mm (7.5 x 4.25 x 14.5 in.); Maximum length on the diagonal – 200 mm (8.6 in.)

Minimum Feature Size: Material and design dependent, as low as 50 μm

Resolution: 4K light engine

Process Energy: UV (385 nm) and thermal

System Size: 49 x 51 x 113 cm (19 x 20 x 44 in.)

System Weight: 81 kg (180 lbs.)

Resin Tray Capacity: 2L

Software: Origin One cloud-based web application

Pre-Certified Materials Include: Biocompatible medical-grade, flame retardant aerospace, & high-impact consumer goods

Explore The Materials

Additive Solutions for U.S. Air Force Sustainment Challenges

The U.S. Air Force increasingly faces sustainment challenges, including cost, speed, and supply chain agility, when using traditional manufacturing methods to maintain aging aircraft components. In 2020, they hosted an open competition to quickly find new and creative 3D printing solutions for the C3175 family of hydraulic line clamps.

Origin One, nTopology, and Stress Engineering Services collaborated on a solution. Leveraging each company’s strength, they were able to create a 3D printed solution in two weeks. The team won the RSO-hosted Advanced Manufacturing Olympics, beating out stiff competition from expert teams and OEMs across the U.S.

Check out the case study to see how they did it!