WRAPCure

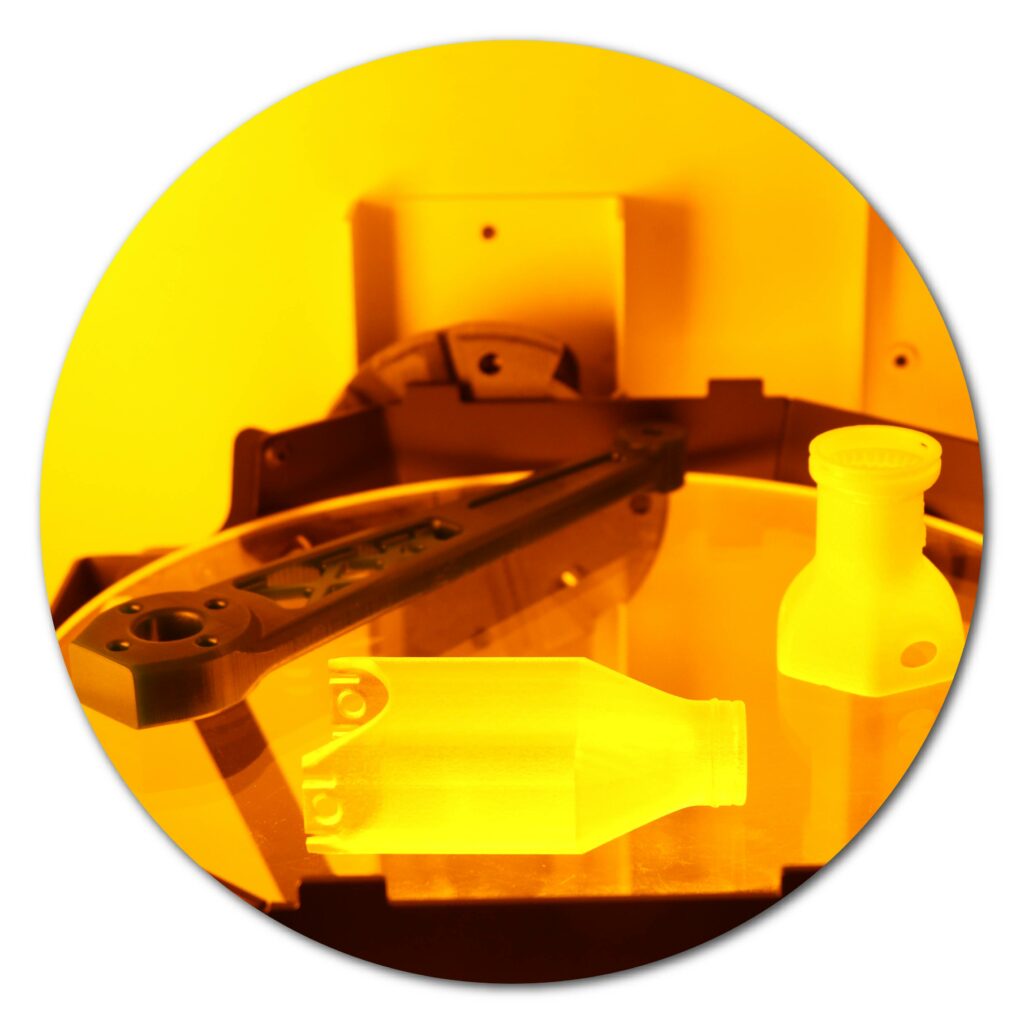

AUTOMATIC DLP POST-CURING

With WRAPCure, the W7500-C builds on the capabilities of the W7500, adding production DLP curing. Using high-power UV lights, microprocessor, and a transparent rotating curing table, the W7500-C ensures automatic and complete part curing. The machine’s dual functionality makes it a great fit for DLP users.

WRAPCure Advantages

Streamline your workflow with best-in-class part curing and waste resin printing.

Dual Functionality

Print waste resin, then switch to final curing of your DLP parts.

Fully Automatic

Save time avoiding manual part repositioning.

Cost Savings

WRAPCure’s LED longevity negates the need for expensive halide bulb replacement.

Repeatable Quality

Properly control temperature and UV wavelength, ensuring mechanical properties and dimensional accuracy.

Novel Architecture

Transparent turntable positioned between UV light sources evenly cures the bottom of your part.

Request A Quote

Applications

No more wasting your time. Turn hazardous waste resin into solid, plastic stock, perfect for a zero-cost CNC machining material and safe for disposal as standard household waste. Turn on WRAPCure mode and automatically cure your DLP parts, saving time on post processing.

Prototype Machining Material

WRAP Mode

Safe Waste Disposal

WRAP Mode

DLP Post-Curing

WRAPCure Mode

Waste Resin Features

- Automatic timing function and integrated safety feature enable unattended operation

- WRAP’s axial printing architecture minimizes overall size and cost

- Through leveraging used or expired resin, operation costs are virtually zero

- Patent pending drip comb produces individual droplets for efficient curing

- Simple gravity-driven drip system avoids use of pumps, valves, and hoses, which are susceptible to clogs

- Onboard carbon filtration system controls fumes

Curing Features

- Fully automatic, hands-free operation

- Microprocessor controlled temperature and duration avoids part warpage

- High wattage LED light arrays

- Converts from WRAP to Cure in under 60 seconds

- LCD user interface

- Adjustable timing functions

See the Specs

Waste Printing Compatibility: PolyJet, Stereolithography, DLP

Vat Capacity: 7.5 L

Throughput: Cures 30 days’ worth of waste resin in 6 hrs.

Printed Plastic Stock: 14 in. dia. x 8 in. dp. cylinder

Post-Processing Compatibility: DLP

Curing Area: 7.5 x 4.25 x 14.5 in.

Curing Time: 5-30 mins., depending on material and part size

System Weight & Size:

Standard: 26.5 x 16.5 x 28.7 in.

Extended: 26.5 x 16.5 x 39.2 in.

Weight: 60 lbs.

Operating Conditions: Temperature between 65 – 95°F (18 – 35°C)

Power Requirements: 100 – 120 VAC, 50 – 60 Hz, 6A,

1 phase (switchable to 220)