WRAPCure Certified

TRACEABLE DLP POST CURING

When using DLP technology, parts are only partially cured as printed. The printed parts require a secondary UV exposure to fully cure and adhere to the material manufacturer’s specifications. Onulis has identified the following critical gaps in the UV post-curing systems currently available.

Solving Industry Gaps

Unwanted Heat Generation

Some solutions use broad spectrum bulbs, which provide unwanted, uncontrolled heat that can warp parts. Manual part rotations are required to avoid warpage.

Onulis’ system uses high-powered, focused UV lights, fully curing parts per manufacturer’s specifications without emitting infrared rays that give off uncontrolled heat.

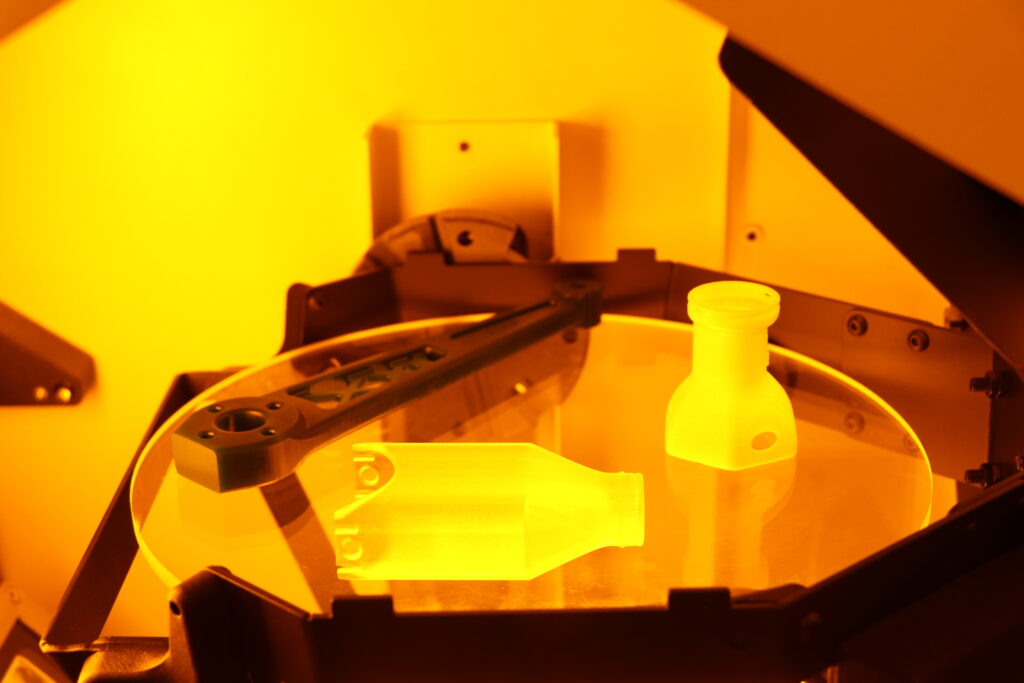

Incomplete UV Part Exposure

No current market offering provide UV exposure to the bottom of parts, so manual rotation is required.

Onulis’ unique system architecture simultaneously exposes all sides of a part to UV light.

Manual Intervention Required

All current solutions require users to manually rotate a part to cure all sides, and avoid warpage.

Onulis provides fully automatic operation.

Lack of Certification, Auditing, & Corrective Action

Today’s offerings do not support ISO 9000 Certified users by providing per unit documentation with each system to define wavelength, irradiance values, and consistency across the curing platform. There are no means to audit the system’s performance over time or a solution for corrective action.

Onulis provides three key elements to ensure lifetime compliance with material manufacturer’s specifications:

- Certification

Each WRAPCure Certified is measured, calibrated, and documented with individual specifications provided with each unit shipped. - Auditing

A Self Audit Kit is available for users to complete in-house audits of their system’s performance. Measurement instrumentation, documentation, and a custom fixture included. This is particularly essential for companies that are ISO 9000 Certified. - Corrective Action

A UV Recharge Pack is available to easily replace a system’s lights and drivers in the event a system falls out of a specification.

Request A Quote

Waste Resin Print Mode

In Print Mode, the WRAPCure Certified automatically converts UV waste resin into fully cured plastic stock for a wide variety of uses, and is safe for disposal as standard household waste.

Using Onulis’ patent-pending WRAP (Waste Resin Axial Printing) technology, the system is the first technology-driven solution for handling UV waste resin, allowing users to avoid time-consuming homespun curing solutions and expensive hazardous waste outsourcing that can draw unwanted oversight from the EPA.

Print Mode Features

- Automatic timing function and integrated safety features enable unattended operation.

- W7500’s axial printing architecture minimizes overall size and cost.

- Through leveraging used or expired resin, operation costs are virtually zero.

- Patent-pending drip comb produces individual droplets for efficient curing.

- Simple gravity-driven drip systems avoids use of pumps, valves, and hoses, which are susceptible to clogs.

- Onboard carbon filtration system controls fumes.

DLP Cure Mode

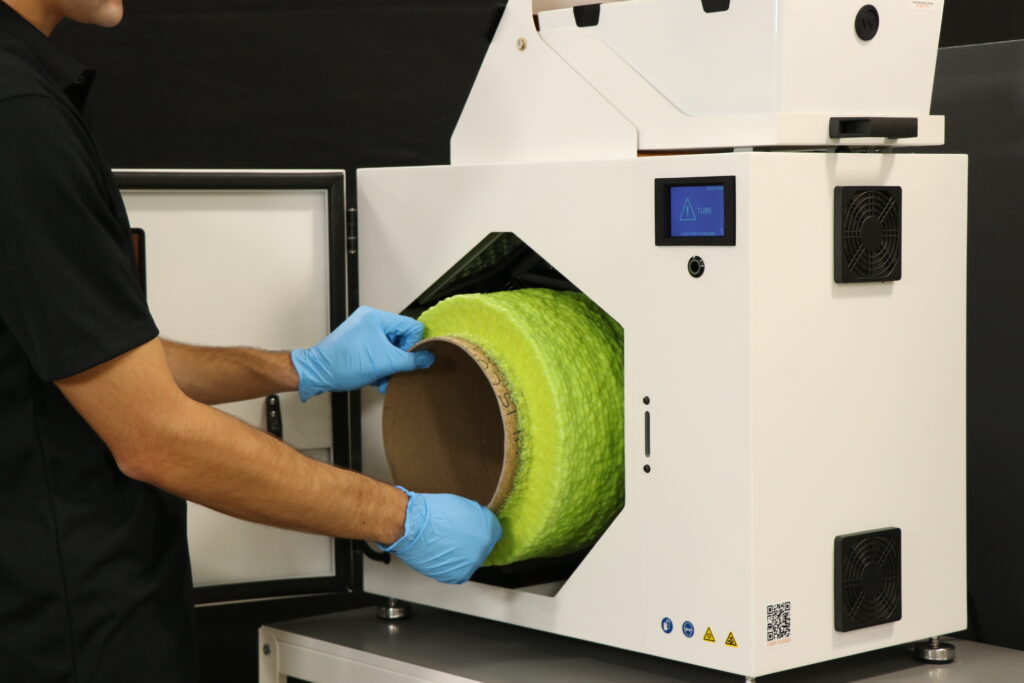

In Cure Mode, the WRAPCure Certified post-cures DLP parts at production speeds. Using high-powered UV lamps and a transparent rotating curing table, WRAPCure Certified offers automatic and complete part curing.

To ensure that the material manufacturer’s specifications will be met, each WRAPCure Certified unit goes through a multi-step calibration, inspection, and documentation process.

Cure Mode Features

- Converts from Print to Cure in < 60 seconds.

- Fully automatic, hands-free operation.

- Traceable curing.

- Microprocessor controlled temperature and duration avoids part warpage.

- High irradiance LED light arrays.

- LCD user interface.

- Adjustable timing functions.

Print Mode Features

Cure Mode Features

- Automatic timing function and integrated safety features enable unattended operation.

- W7500’s axial printing architecture minimizes overall size and cost.

- Through leveraging used or expired resin, operation costs are virtually zero.

- Patent-pending drip comb produces individual droplets for efficient curing.

- Simple gravity-driven drip systems avoids use of pumps, valves, and hoses, which are susceptible to clogs.

- Onboard carbon filtration system controls fumes.

- Converts from Print to Cure in < 60 seconds.

- Fully automatic, hands-free operation.

- Traceable curing.

- Microprocessor controlled temperature and duration avoids part warpage.

- High irradiance LED light arrays.

- LCD user interface.

- Adjustable timing functions.