AFFORDABLE 3D PRINTING

UltiMaker

Next-generation desktop 3D printing platform, delivering manufacturing-grade parts with advanced engineering materials.

Industrial 3D Printing For Everyone

Breakthrough technologies from UltiMaker leveraging patents from Stratasys – the worldwide leader in industrial 3D printing.

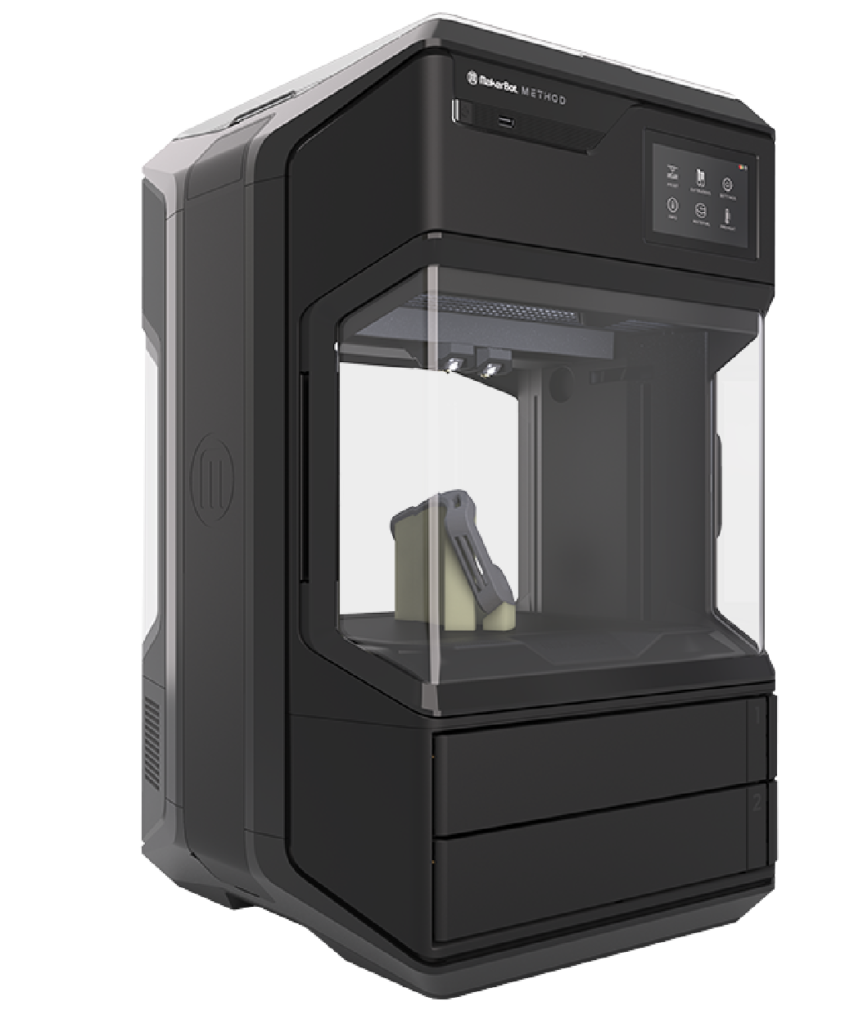

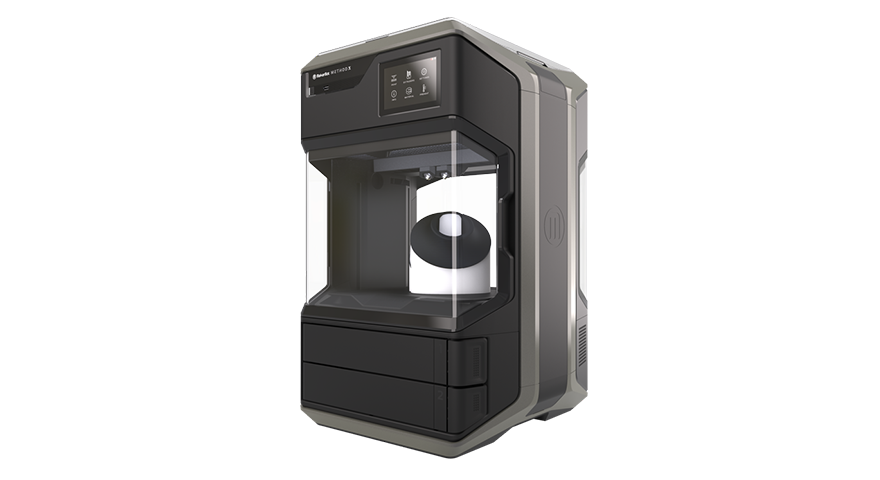

Method

Print a selection of MakerBot polymers to guaranteed dimensional accuracy spec with the aid of a 65°C heated chamber.

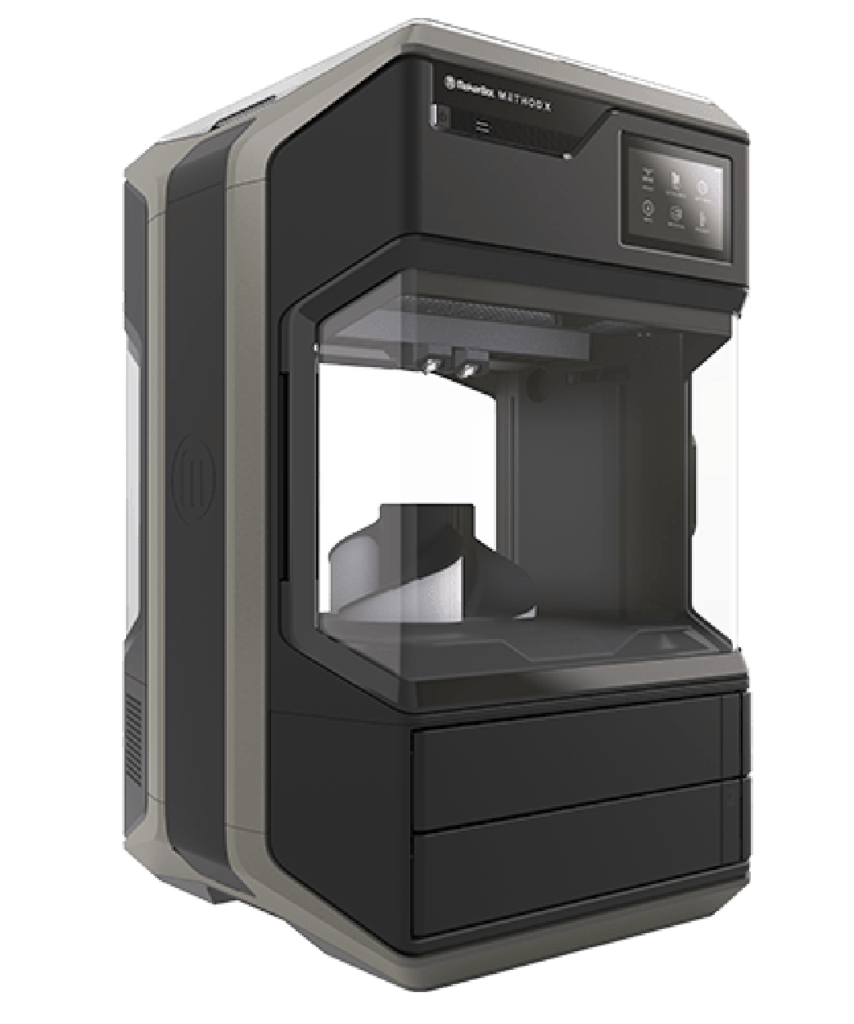

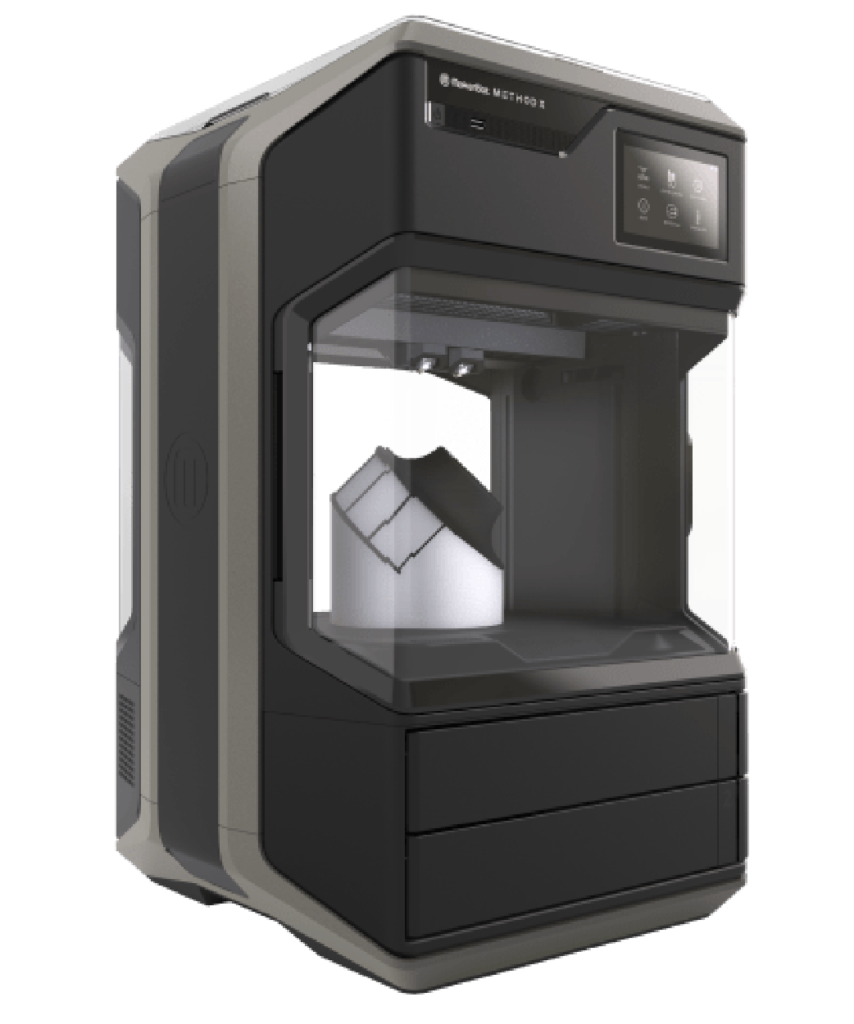

Method X

Print the full catalog of MakerBot polymers and composites with superior accuracy and strength in a 110°C heated chamber.

Method Carbon Fiber

Print carbon fiber reinforced nylon and other engineering-grade composite parts with high strength and accuracy on MakerBot’s unique industrial desktop platform.

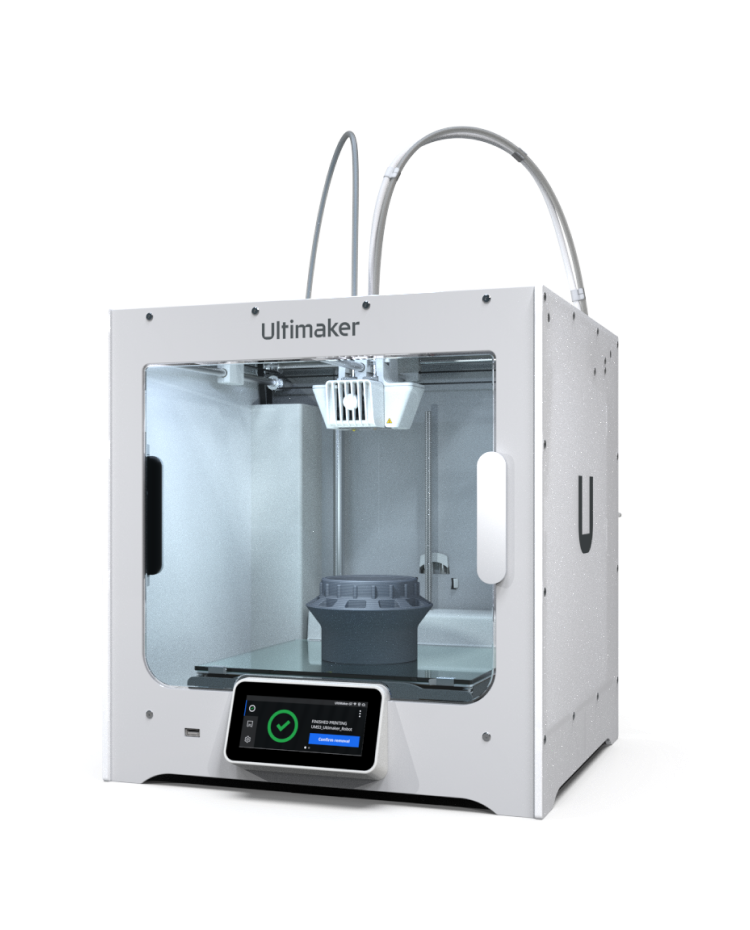

Ultimaker S3

A powerhouse that fits perfectly on a desk. Ready to print glass and carbon fiber composites. Soluble supports allow for complex geometries with more design freedom.

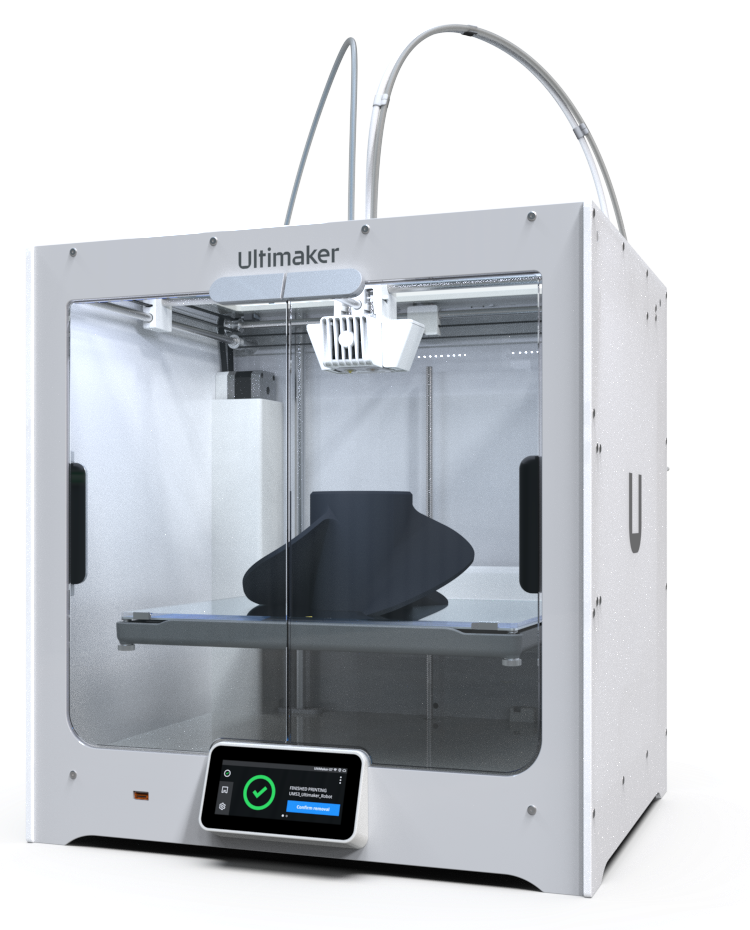

Ultimaker S5

Ideal for bringing big ideas to life. Simply click and print with the widest choice of materials on the market – including reinforced composites and stainless steel.

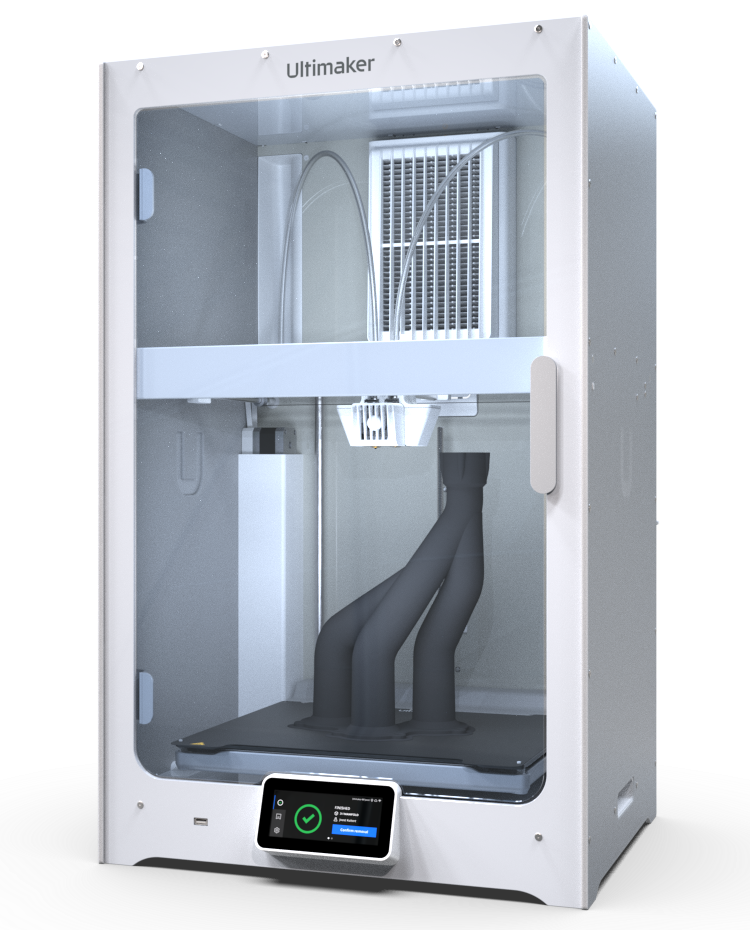

Ultimaker S7

Always achieve a perfect first layer thanks to inductive probing and bed tilt compensation.

Ultimaker S7 Pro Bundle

Bigger capacity. Better productivity. This is the complete solution to revolutionize your workflow. Spend less time managing materials and more time producing high-quality parts.

Request A Quote

Explore the Lineup

Method

- Composite direct drive extruders

- Heated chamber up to 110°C

- ABS direct drive extruders

- Heated chamber up to 110°C

- Dual direct drive extruders

- Heated chamber up to 65°C

- Enclosed printer with particulate filter

- Heated and flexible buildplate

S Series

Ultimaker S7 Pro Bundle

- Material handling for 6 spools

- Flexible buildplate

- Accurate inductive probing

- Compatible with 280+ materials

Ultimaker S7

- Integrated Air Manager

- Flexible buildplate

- Accurate inductive probing

- Compatible with 280+ materials

Ultimaker S5

- Large build chamber

- Compatible with 280+ materials

- Optional Air Manager

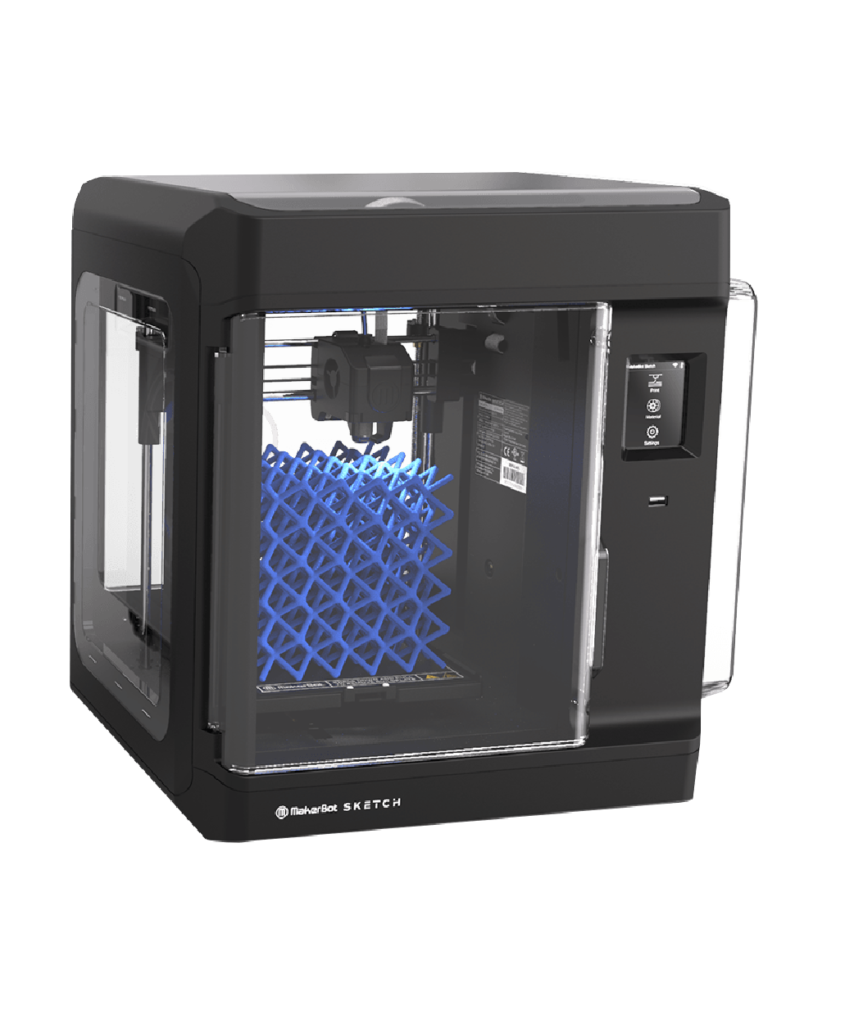

Ultimaker S3

- Dual extrusion print cores

- Compatible with 120+ materials

- Filament run-out sensors

Why Customers Love UltiMaker

BOSEbuild

The BOSEbuild team needed a quicker and more cost-efficient way of designing and testing parts for their headphones. After incorporating UltiMaker S Series 3D printers into their workflow, BOSEbuild has reduced their prototyping costs to $1-$2 per part for only a few hours of printing, leaving room for product testing.

Jamco America

A wide-array of functional prototypes have been printed using the UltiMaker Method 3D printer. The team at Jamco America has recently been using their printer to produce a dual latch system for an aircraft privacy door. With 3D printing, the team has been able to find a 96% reduction in prototyping costs and a 95% reduction in turnaround time.