You would think after 13 years of working at Purple Platypus, Jason Lasunowicz, one of our Field Service Technicians, would already have a favorite part in our showroom. But by the look of pure panic on his face when I asked him to choose one for Part of the Month, I guess he doesn’t. He shot straight up and started pacing the showroom floor, grabbing part after part from the shelves. Carrying about 10 parts in his arms, he dumped them onto my desk and told me he was having a hard time deciding.

Jason has seen the evolution of 3D printing through the many years he has been at Purple. He has witnessed PolyJet grow from single material to multi-material, and then to full color. With the wide variety of awesome PolyJet parts in our office, I understand his dilemma. Over the course of 3 days, Jason visited my desk, slowly but surely, narrowing down his options. (And slowly but surely, cleaning off my desk by returning the parts to their shelves.)

Finally – I’m not sure if it’s because he is a Service Technician and is constantly working with the insides of 3D printers or he is secretly a tech fanatic – he chose a PolyJet circuit board.

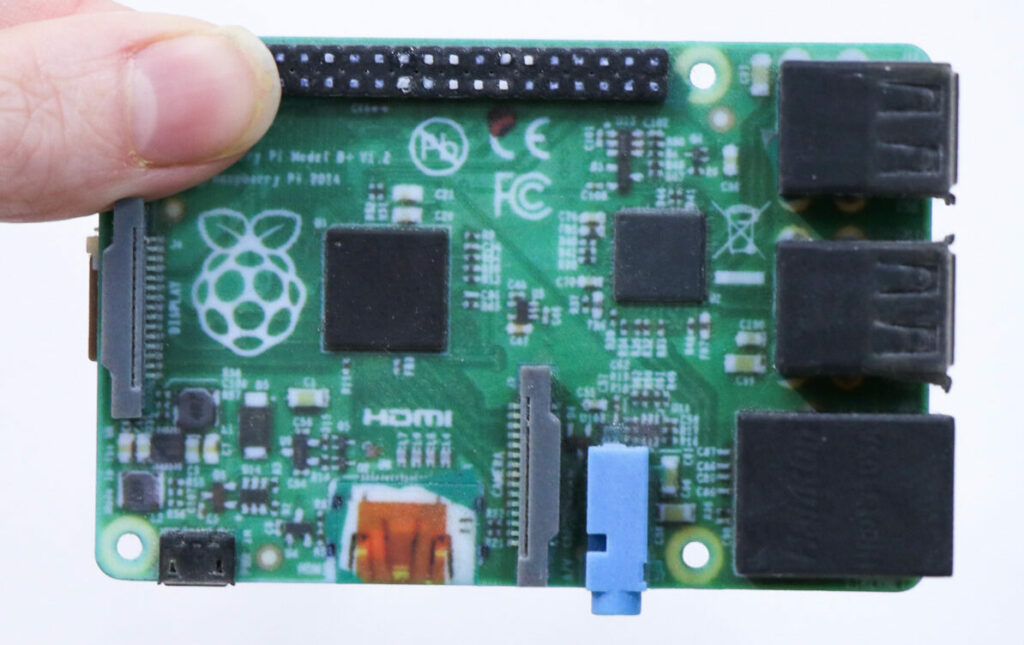

This lifelike model of a circuit board showcases many of the unique features of PolyJet 3D printing, such as full color, realism, and multi-material printing, which is exactly why Jason chose it. From the micro-SD card reader to the USB port, it shows every part of an actual circuit board. (If you look at the back side of the print, it even shows the capacitors, soldering pins, and some replica clips for the ethernet port.)

The circuit board was printed on a legacy J750 printer, using Vero and a little bit of Agilus – to make the USB ports slightly flexible. On the J850, the colors would be more vivid, and the flexible portions could be colored using Agilus CMY. All the protruding parts, like the ports, audio jack, and input/output pins, were printed directly on the circuit board in a single part. This is to say, no assembly required. Likewise, no coloring or painting of the part is necessary.

The fact that Jason can still get excited about a PolyJet part we have had for years just goes to show how amazing PolyJet technology is and where it’s headed. The parts off PolyJet 3D printers are continuing to become more eerily realistic as Stratasys continues to innovate.

If you are interested in learning more about the J850 or PolyJet 3D printing, give us a call at 949.474.9222 or email us at [email protected].

Meet Jason Lasunowicz

Meet our Field Service Technician, Jason Lasunowicz. If you ever want to expand your knowledge on the ins and outs of Stratasys technology, Jason is one of our printer masterminds. He installs and maintains all of our Stratasys machines. What Jason loves most about working at Purple is the amount of teamwork involved in the everyday workflow at the company. He also enjoys all of the amazing people he gets to meet on a daily basis.

Out of the office, Jason enjoys going to Knott’s Berry Farm, playing video games, and spending time with his family. If you haven’t had the chance to meet Jason, make sure to stop by the office or connect with him on LinkedIn!