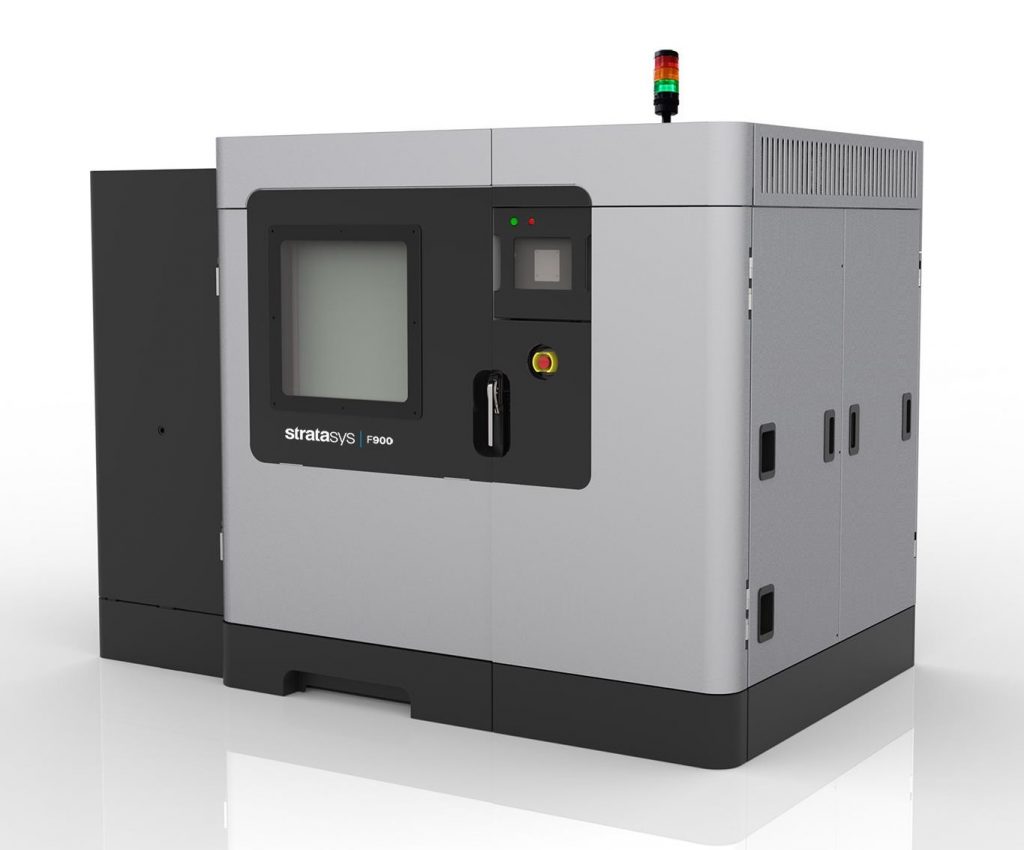

ULTIMATE PRODUCTION SYSTEM

F900

With the largest build size of any Fortus system, the Stratasys F900 is designed to handle the most demanding manufacturing needs.

Think Big

Rely on the F900 to achieve real manufacturing with 3D printing.

The accuracy, repeatability, and predictability of the F900 are unmatched, and the control system leverages the system’s hardware to deliver superior throughput and reliability.

The F900 uses engineering-grade thermoplastics to build robust production parts, jigs, fixtures, factory tooling, and functional prototypes. Large parts are printed fast with slice heights up to 0.020 inches to help meet production demands with ease.

The machine offers a streamlined workflow and easier job monitoring with an internal camera, GrabCAD Print software, Insight, and MTConnect readiness. Standard certifications are included and reduce workload to qualify 3D printing for your production floor.

Request A Quote

See The Specs

Build Size: 914.4 x 609.6 x 914.4 mm (36 x 24 x 36 in.)

System Size & Weight: 2,772 x 1,683 x 2,027 mm (109.1 x 66.3 x 78.1 in.); 2,869 kg (6,325 lbs.)

Stratasys Preferred Materials: ASA, ABS-M30, ABS-M30i, ABS-ESD7, Antero 800NA, Antero 840CN03, PC-ABS (Black), PC-ISO, PC (White), ULTEM™ 9085 (Tan, Black), ULTEM™ 1010, PPSF, FDM Nylon 6, FDM Nylon 12, FDM Nylon 12CF, ST-130

Stratasys Validated Materials: FDM HIPS, Kimya PC-FR, ULTEM™ 9085 (Red, White 7362, Jana White, Gunship Gray, Dream Gray, Aircraft Gray), PC (Red), PC-ABS (Red)

Explore The Case Studies

Reaching New Heights of Efficiency

“The… 3D printer offers us the enhanced geometric freedom to create previously unthought-of 3D printed tools, which enable us to manufacture extremely complex parts that would be uneconomical or just physically impossible to create by any other means.”

Rachel Trimble / GKN Aerospace

Empowering Design and Production Innovation

“Having this on-demand production capability enables our engineers to take advantage of the greater design freedom enabled by 3D printing, which has empowered Marchesini Group to achieve higher-quality results for our customers.”

Mirko Fortunati / Marchesini Group