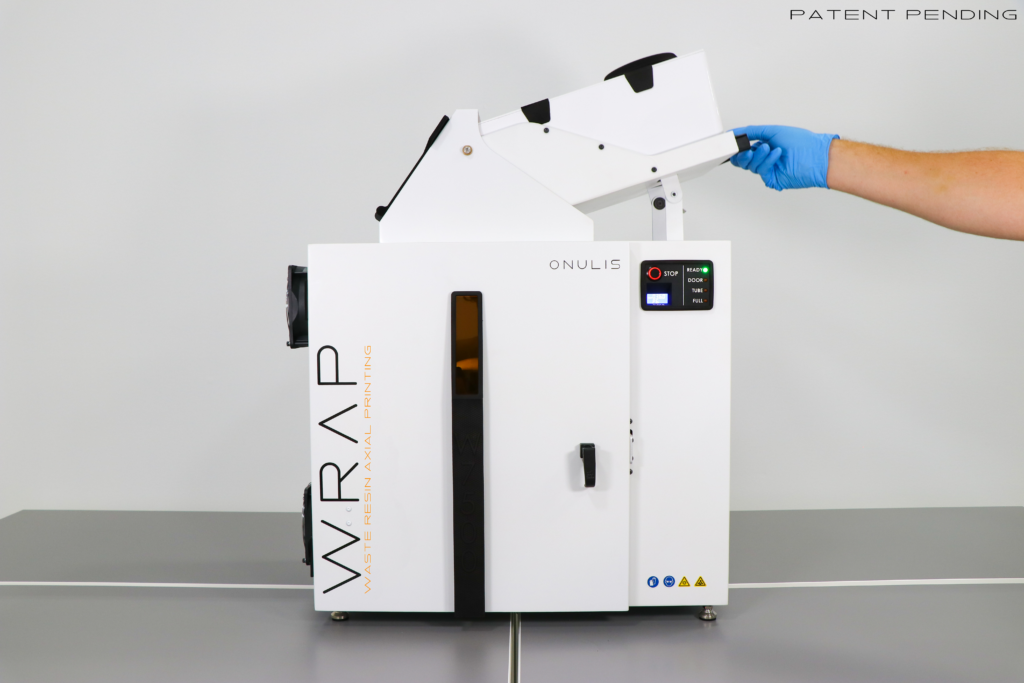

W7500

WASTE RESIN AXIAL PRINTING

The W7500 printer transforms UV waste resin into solid plastic stock, safe for disposal as common household waste. The solid stock it produces can also be used for a wide variety of applications, including low-cost media for prototype machining, raw material to produce colorful products, and unique organic shapes for artwork projects.

Built by Onulis and leveraging the patent pending WRAP™ (Waste Resin Axial Printing) technology, the machine allows users to make hazardous resin safe.

Turn Waste Resin Into Solid Plastic

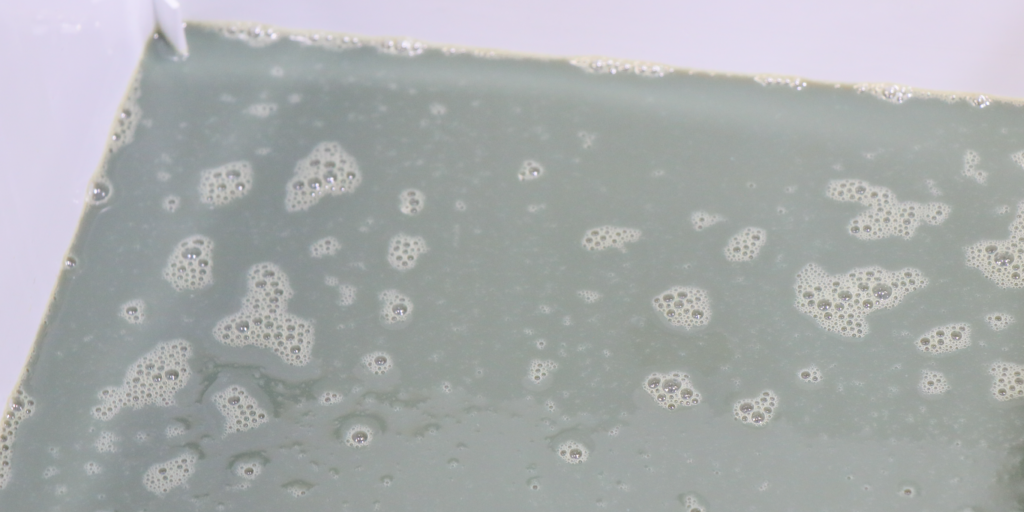

Before

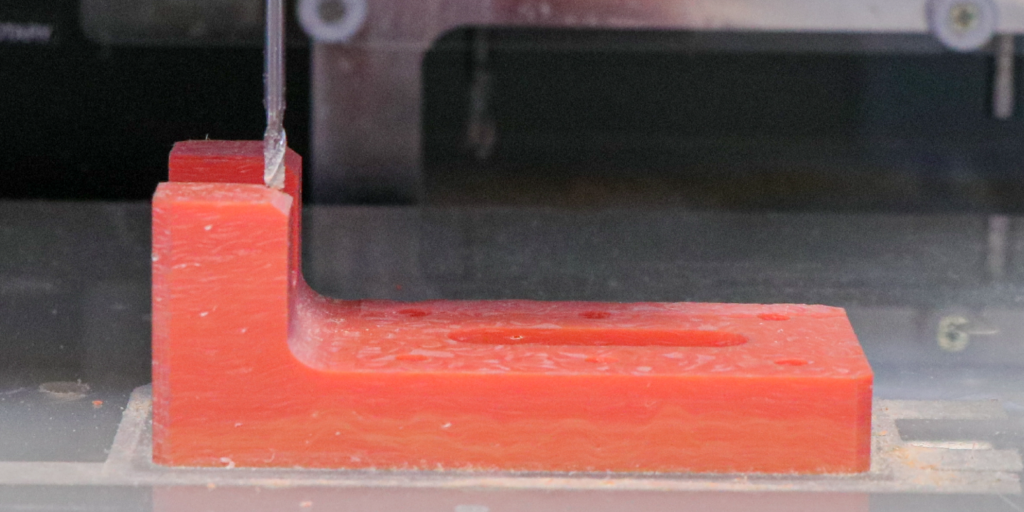

After

Fully Automatic Operation

Use zero-cost waste resin to create solid plastic products which can be disposed of safely.

Compact & Cost-Efficient

W7500’s axial printing architecture minimizes its overall size and cost. Through leveraging used or expired resin, operation costs are virtually zero.

Easy Operation

Automatic timing function and integrated safety features enable unattended operation.

Office-Friendly

Simple gravity driven drip system avoids use of pumps, valves, and hoses, which are susceptible to clogs. Plus, the onboard carbon filtration system eliminates any fumes.

Request A Quote

Applications

Turn hazardous PolyJet, SLA, and DLP waste resin into solid plastic stock, safe for disposal as standard household waste.

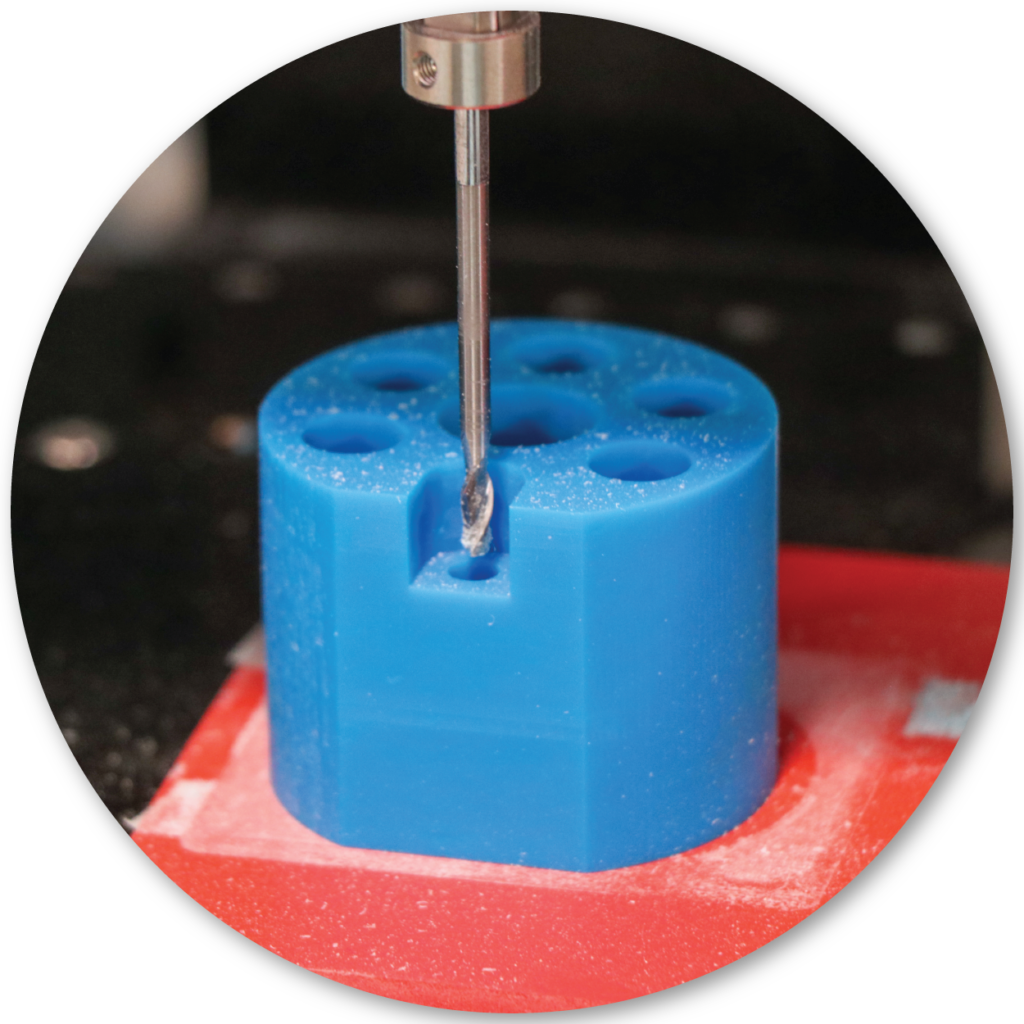

Prototype Machining Material

Safe Waste Disposal

Colorful Artwork Projects

See The Specs

Vat Capacity: 7.5 L

Throughput: 1L/hr

Compatible Resins: PolyJet, SLA, DLP

Hardened Waste Size: 14″ dia. X 8″ lg. cylinder

Standard System Size: 26.5″ (W) x 16.5″ (D) x 28.7″ (H)

Extended System Size: 26.5″ (W) x 16.5″ (D) x 39.2″ (H)

Storage Stand: 28″ x 22″ x 18″

The optional storage stand is designed to position the WRAP™ W7500 at the optimal height for loading resin and removing the final mandrel. The stand conveniently fits up to 12 disposable mandrels.

Have a DLP Machine? Automatically cure your DLP parts after printing with the post-curing solution, WRAPCure. This dual function waste resin printer is a must for all DLP users.