OPTIMIZE QUALITY CONTROL

& REVERSE ENGINEERING

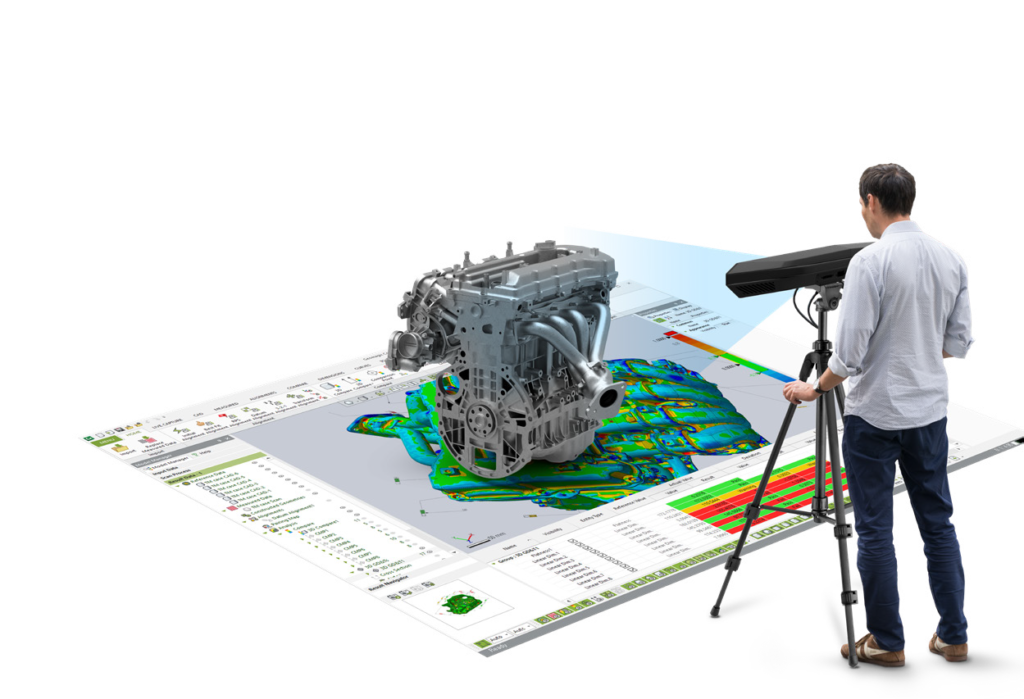

Quadro+

The Quadro+ can be used in an array of applications, from quality control to reverse engineering. The versatile machine is the first 3D scanner that is ready to scan in any almost any condition.

Versatile 3D Scanning

Featuring 12 Mpix and 9 Mpix cameras with two scanning ranges in one unit, the Quadro+ allows you to scan large-frame parts and fine features. Switching between scanning ranges is simple, as you can move between the inner and outer focal range without changing the lens on the camera itself.

The Quadro+ is your dedicated solution for factories and all types of production lines. Unlike other 3D scanners on the market, the Quadro+ was designed to work in even the harshest conditions.

Whether you’re looking to optimize your quality control or reverse engineering process, this 3D scanner works well in a wide variety of applications and industries.

Request A Quote

What Makes It Different

“The funny story we have here at Purple, is when we first got the scanner in, powered it up, scanned a sample part, we actually thought there was maybe an issue with the mesh we were gathering. We were scanning an FDM 3D printed part and it was so accurate that it was actually picking up the layer lines on the FDM part. We hadn’t seen a scanner that could do that before.”

– Peter Montgomery, Senior R&D Engineer

See The Specs

The Quadro+ guarantees precise measurements in harsh environment. Two ranges enable to scan objects of different dimensions: from a few centimeters to several meters.

Scanning Time: 1.2 seconds

Scanning Accuracy: up to 0.007 mm

Camera Resolution:

Outer – 9 Mpix

Inner – 12 Mpix

Measuring Ranges:

Outer – 450 x 225 x 180 mm

Inner – 220 x 160 x 90 mm

Point Density:

Outer – 88 pts/mm²

Inner – 351 pts/mm²

Software: eviXscan 3D Suite

Reverse Engineering

The Quadro’s ability to capture high-resolution geometry with its 7 micron scanning accuracy means that it can scan complex, detailed objects, allowing you to reverse engineer a wide variety of parts. From large aerospace parts to small medical parts, you can use CAD data to regenerate the geometry.

To learn more about reverse engineering on the Quadro+, check out our 30 on 3D episode or request a quote.

Quality Control

The Quadro’s accuracy of up to 0.007 mm and point density of up to 351 pt/mm2 makes it a perfect solution for quality control checks. When combined with eviXscan 3D Suite, the Quadro+ allows users to streamline the quality control process. Some of the tools included within the software include scan processing automation, deviation location, and airfoil analysis.

To learn more about quality control on the Quadro+, check out our 30 on 3D episode or request a quote.