ACCELERATE PRODUCTION

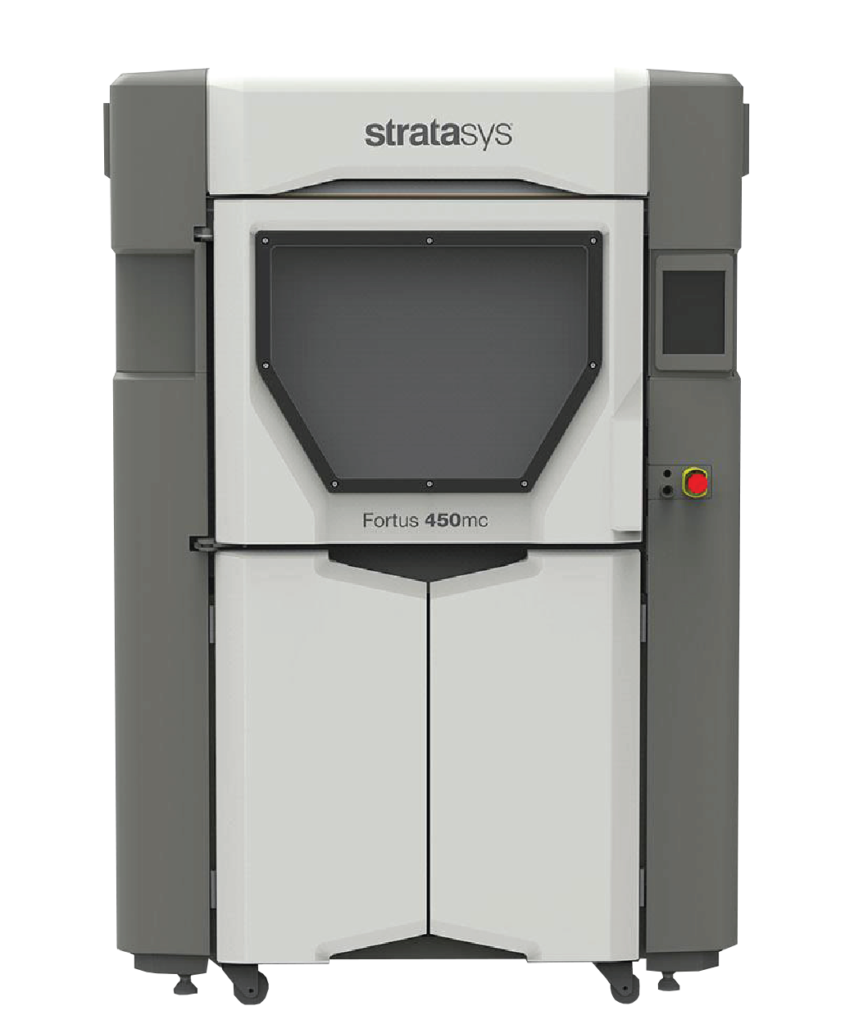

Fortus 450mc

Minimize cost, increase uptime, and improve quality on your factory floor. From functional prototypes with exacting tolerances to manufacturing tools that perform under pressure, the Fortus 450mc production system sets a high bar for speed, performance, and accuracy.

High-Performance Production Printing

Built for streamlined manufacturing.

Quickly build advanced prototypes and production aids as large as 16 x 14 x 16 in. Plus, run high-performance thermoplastics for specialized production parts in demanding fields, such as medical, aerospace, research, and defense.

The Fortus 450mc Production System was designed to build high-requirement prototypes, rugged jigs, fixtures and tooling, and custom production parts in familiar thermoplastics.

Request A Quote

See The Specs

Get to market faster with the Fortus 450mc, which provides a multi-application manufacturing solution that reduces design and build times, optimizes manufacturing workflows, decreases overall costs, and promotes factory innovation.

Build Size: 406 x 355 x 406 mm (16 x 14 x 16 in.)

Material Delivery Options: Two bays for each material and support canisters. Auto changeover between canisters.

System Size & Weight: 129.5 x 90.2 x 198.4 cm (51 x 35.5 x 78.1 in.); 601 kg (1325 lbs.)

Material Options: ABS-ESD7, ABS-M30, ABS-M30i, Antero 800NA, Antero 840CN03, ASA, FDM Nylon 12, FDM Nylon 12CF, PC, PC-ABS, PC-ISO, ULTEM™ 9085 Resin, ULTEM™ 1010 Resin, ST-130

Software Options: GrabCAD Print, GrabCAD Print Pro, Insight

Explore The Case Studies

“The single 3D-printed piece replaced an assembly of 22 machined metal components and is about 98% less expensive to manufacture.”

Liam Johnston / Program Manager, John Crane

“Not only do we enjoy a cost saving, but thanks to the ability to 3D print a customized part on-demand, there is no minimum order requirement.”

Alex Karetny / Pack Line Ltd.