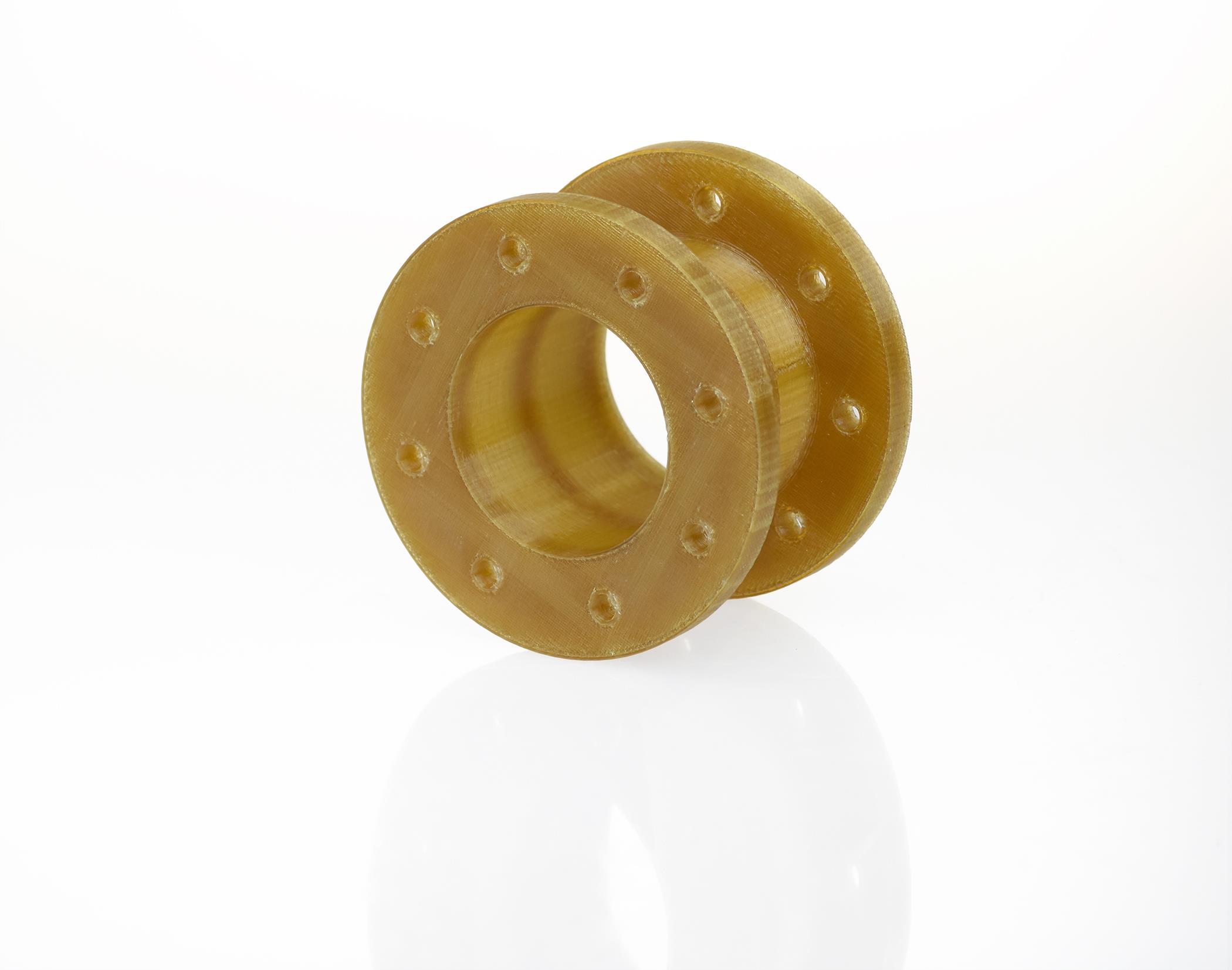

Antero 800NA

PEKK-Based FDM Thermoplastic

Antero 800NA combines FDM’s design freedom and ease of use with the excellent strength, toughness and wear-resistant properties of PEKK material. This advanced material exhibits high heat resistance, chemical resistance, low outgassing and dimensional stability, particularly in large parts.

3D Printing With Antero 800NA

3D printing with Antero 800NA produces complex and low-volume parts faster, cheaper, and lighter. Using Antero with FDM technology avoids the waste and design limitations associated with subtractive manufacturing of high-cost bulk PEKK material. Available on the Fortus 450mc, Antero 800NA is great for industries such as:

Oil and Gas – Custom fixtures and electrical connectors

Aerospace – Parts that require chemical and temperature resistance, as well as certification. Part types include:

- Clips, brackets, and clamps used In and out of cabin applications, where parts are exposed to cleaning chemicals, fuels or hydraulic fluids, or high-temperature performance is important

- UAV – high temperatures near engine or chemical resistance required

- Ducting

- High requirements tooling

Space – Materials that are intended for use in space vehicles, associated ground support equipment, and facilities used during assembly, test, and flight operations both require materials with high-temperatures stability, and low outgassing.

Industrial Manufacturing – PEKK parts used for chemical exposure. Part types include:

- Custom and specialty tooling with high usage temperatures

- Clean room compatible tooling

- Jigs and fixtures – high-end tooling or jigs used for testing electronics assemblies