After the CHIPS Act passed, everyone became an expert on ‘electronics manufacturing’ without understanding the material requirements to work in the space. Thanks to a project with integrated circuit manufacturers, I have a better understanding of electronics workflow and found opportunities for 3D printing to provide value.

When evaluating whether a material is suitable for sensitive electronic cleanrooms, we look for materials to:

Minimize particle generation:

• No Shedding (Sloughing)

• Minimal Outgassing

• Cleanability

Be safe for contact with sensitive electronic components:

• Electrostatic Discharge (ESD) Properties

• High Accuracy

Have documentation:

• Material Tests

• White Papers

• Traceability

Purple Platypus can meet and exceed those requirements with several materials and printing methods from Stratasys. Let’s evaluate some 3D printed electronic manufacturing tools, as well as the machines and materials used to create them.

Pick-Up Nozzle For Electronic Components

Our latest high-end DLP printing technology is the ideal solution for producing intricate, device-specific components for PCB Pick & Place machines and Semiconductor Test Handlers, like the one pictured below. In a matter of hours, users can manufacture thousands of components of varying sizes and complexity.

The technology enables the use of unique engineering materials. This vacuum nozzle is made of high-strength, non-particle generating plastic. The use of ESD plastic in this application helps protect valuable electronic components against static discharges, which are typical in applications where there is focused airflow.

Printer: Origin One

Print Size & Time: The pictured part is 0.9 in. tall. 10 copies of it can be printed at once on the Origin One, in under an hour.

Material: Formula1 by Mechnano

Formula1 uses a stable dispersion of carbon nanotubes to achieve consistent static dissipative properties. The material creates parts with no carbon trails and has high tensile strength and impact resistance.

JEDEC Tray

Recent supply chain issues have accelerated the push to bring manufacturing in-house. Take, for instance, a JEDEC tray. A JEDEC tray is used for transporting, handling, and storing complete chips and other components. It has detailed components and must be made with an ESD material.

The resulting part is high resolution with isotropic static dissipative and mechanical properties. It is safe for direct contact with integrated circuits and other sensitive electronics.

A JEDEC tray is a start, but also SMT nozzles, wafer boxes, and more can be manufactured with 3D printing.

Printer: Origin One

Print Size & Time: The pictured JEDEC tray is 12.7 x 5.5 x 0.25 in. With the Origin One machine you can print 5 trays at once, in less than 12 hours.

Material: Formula1 by Mechnano

Housing & Shields

The line between functional testing and production are increasingly blurred. 3D printing allows for functional prototypes, with the strength, durability, and quality to be used as a final part.

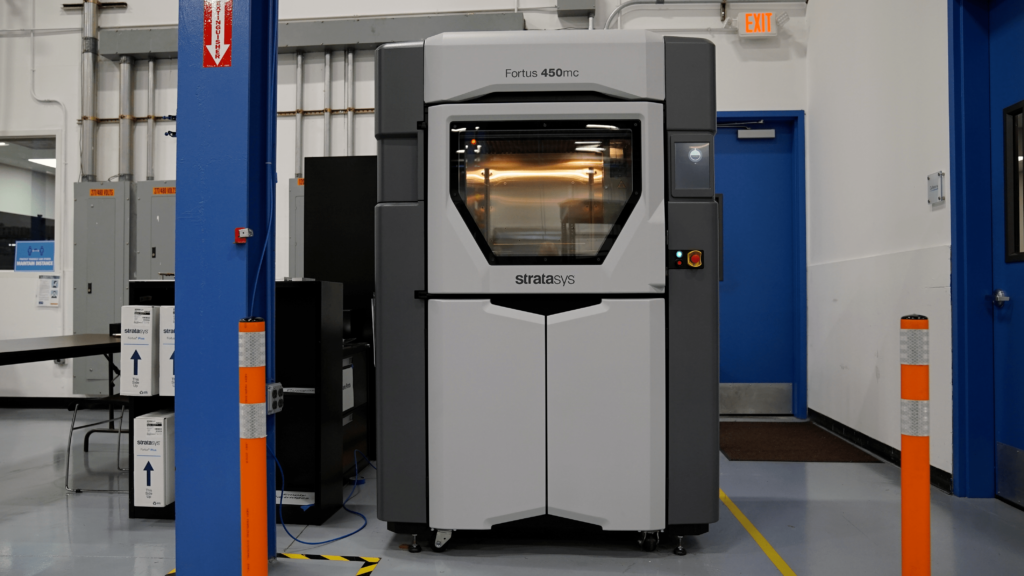

Printer: Fortus 450mc

Print Size & Time: The avionics box pictured below consists of three separate pieces that can all be printed on one build platform, with the resulting box sized at 6.25 x 3 x 3 in. The print takes less than 10 hours.

Material: Antero

ESD Option Available: Yes, Antero 840CN03

Antero 840NC03 is a PEKK-based thermoplastic that combines the excellent physical and mechanical qualities of PEKK with ESD properties.

Production Support

The value-add of 3D printing has been seen for years in the creation of jigs and fixtures. Most manufacturing floors have a 3D printed fixture to improve workflow or ergonomics.

Printer: F370

Print Time: Under 45 minutes.

Material: ABS

ESD Option Available: Yes, ABS-ESD7

ABS-ESD7 is an ABS-based thermoplastic with static dissipative properties, ideal for static-sensitive applications. It’s easy to print with and the F370 can be integrated in a cleanroom or office setting.

Companies can find tremendous value in 3D printing. But, with the array of technologies, machines, and materials, figuring out where to start can feel like a barrier to entry. At Purple, our goal is to help companies evaluate the potential time and cost savings of 3D printing, and determine what printer is the right fit for their needs.

If you’d like more information and a quote on one of our printers, contact us online or at 949.474.9222. If you’d like to have a few parts printed by our Service Bureau, upload your files here or send us an email at [email protected].

Meet Hudson Romain

Meet Sales Engineer, Hudson Romain. Hudson strives to find innovative solutions for designers, manufacturers, and engineers working in every industry. His favorite part about working at Purple Platypus is that he gets to work with people in unique industries, from toys to aerospace.

Out of the office, Hudson enjoys tinkering with engines and circuit boards, playing beach volleyball, and hanging out with friends. If you haven’t had the chance to meet Hudson, be sure to connect with him on LinkedIn!