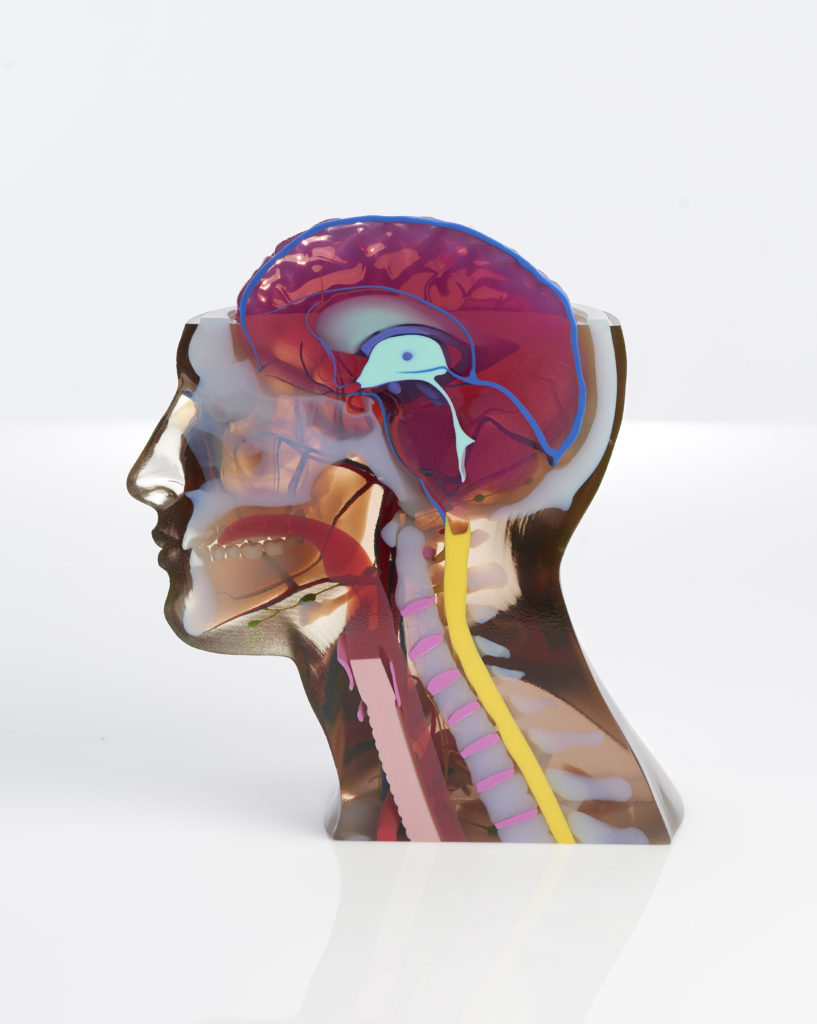

Creating unique and visually stunning prototypes has never been easier. For simple prototypes, Stratasys PolyJet machines generate detailed and effective models.

But with projects requiring multi-body assemblies, full-color options, and over-molds – Stratasys truly reigns supreme. CMYKW rigid materials allow for a full spectrum of colors, while rubber-like materials allow for features at different shore durometer values.

The phrases full color printing, over-molding, and multi-body assemblies may seem somewhat self-explanatory, but the “how to” may not be so obvious.

Full Color Printing

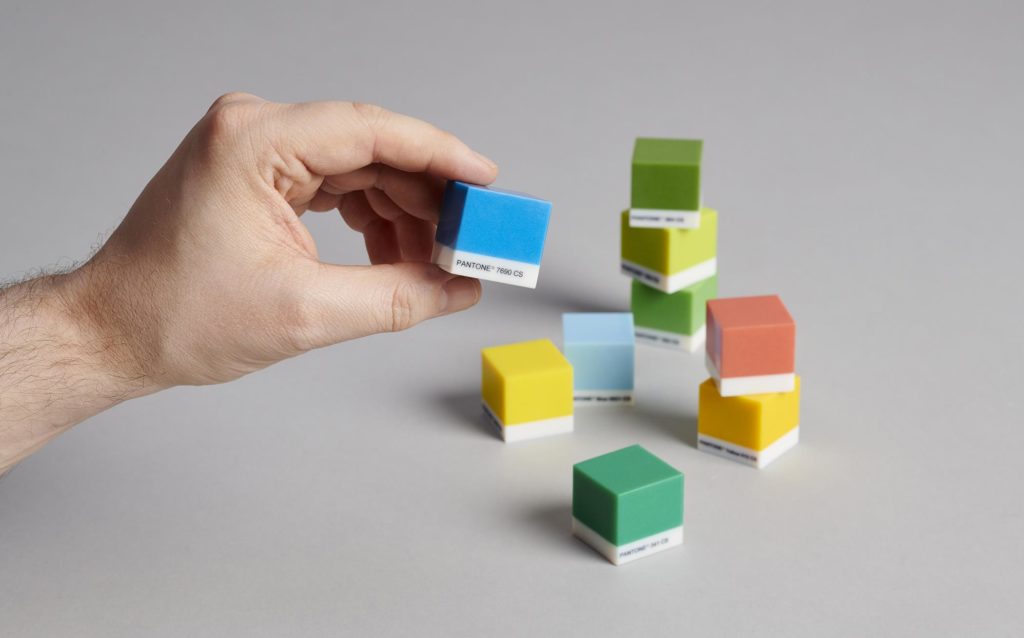

With full color printing, you can create incredibly detailed colored models. Purple Porcupine’s 3D printing services leverage six different colored materials, including Pantone Validated Colors.

Designs can be printed in full color by selecting color values in the print software or by wrapping the 3D geometry with colored textures before sending it to print. In either method of color application, the machine will jet and blend multiple materials to attain your color goals.

Designs can be printed in full color by selecting color values in the print software or by wrapping the 3D geometry with colored textures before sending it to print. In either method of color application, the machine will jet and blend multiple materials to attain your color goals.

With Pantone Validated Colors, our team of experts can ensure that your desired color will be accurately represented in the final model.

Over-Molds

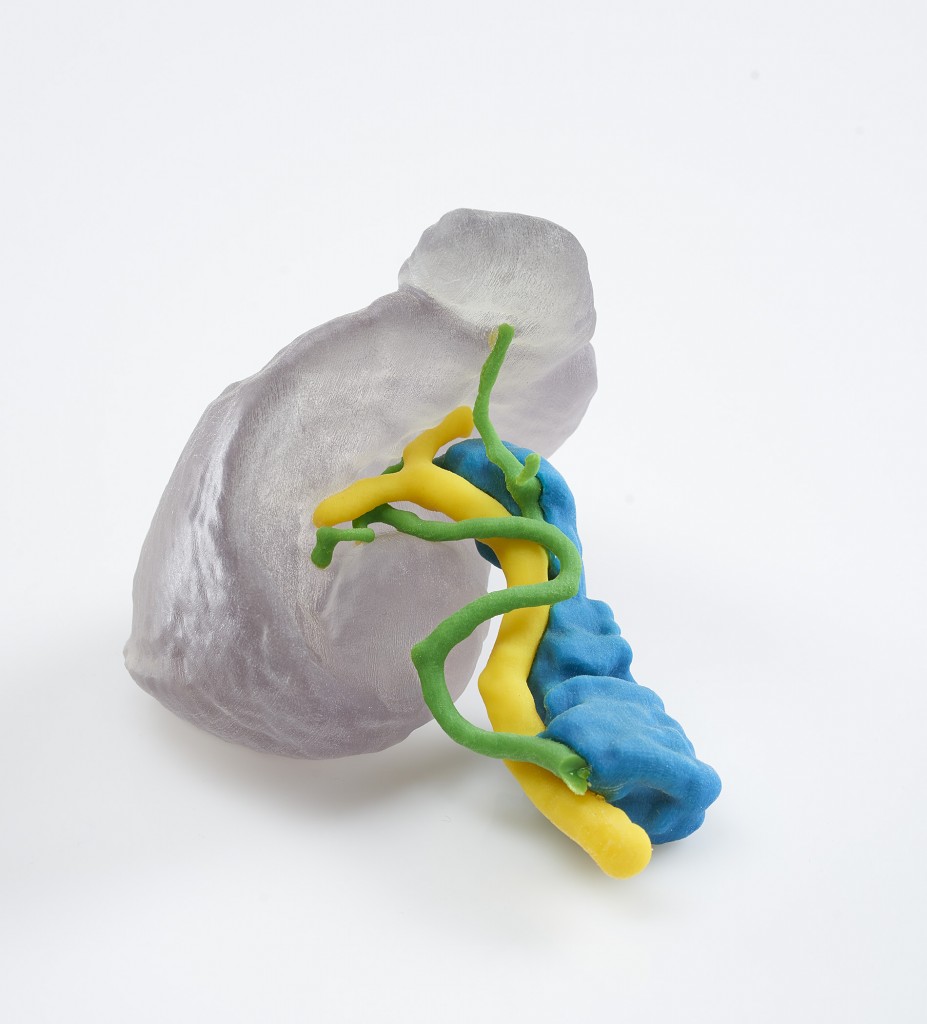

Over-molding is the practice of molding one substrate around or onto another substrate. Typically, the two substrates have different properties to them, either variances in mechanical properties or color values, and are done in separate stages.

PolyJet can streamline the over-molding process, creating both substrates in a single print.

Often, when designing a rubber over-mold, there is a desired shore durometer to influence aesthetics or perform a certain function. Shore durometers are categorized from “softer” or more malleable materials to “harder” materials that are less prone to indentation. Within this metric system, the ”softer” materials are given a lower numerical value and the “harder” materials are given a numerical higher value. As of now the available shore values are between shore 30 A – shore 95 A.

Often, when designing a rubber over-mold, there is a desired shore durometer to influence aesthetics or perform a certain function. Shore durometers are categorized from “softer” or more malleable materials to “harder” materials that are less prone to indentation. Within this metric system, the ”softer” materials are given a lower numerical value and the “harder” materials are given a numerical higher value. As of now the available shore values are between shore 30 A – shore 95 A.

On a PolyJet machine, we can adjust the design by selecting your desired shore values when putting the part to print. The printer will take this designation and jet out a specific amount of rigid and rubber-like materials, while again blending on the platform.

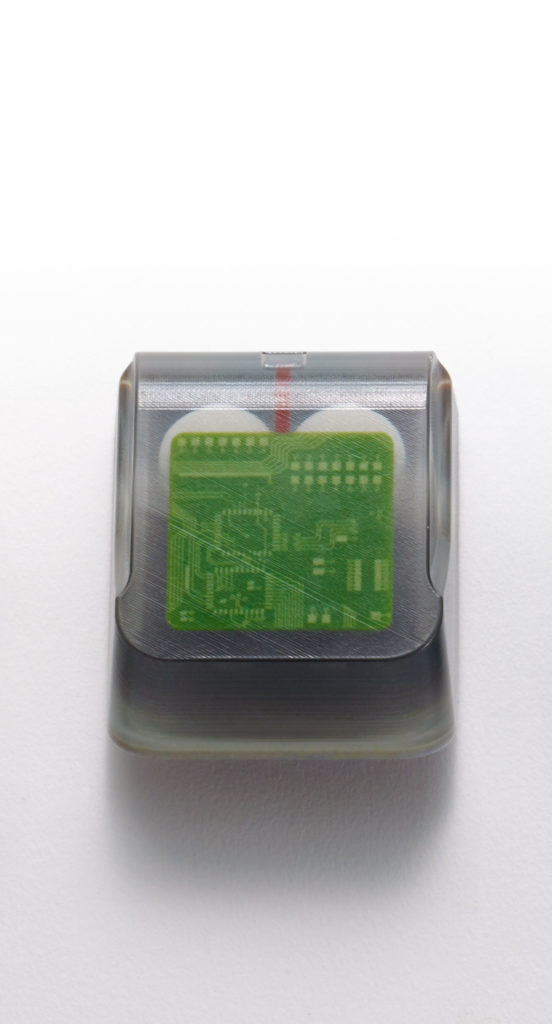

Multi-Body Assemblies

Multi-body assemblies describe parts that require color, over-molds, or both.

When creating multi-body assemblies, there is an important practice to make sure that your builds have the intended outcomes. Let’s go a little deeper about how your parts should be designed in CAD and presented to the printer.

If you know that your part will have different material properties or colors values across surfaces or features, building separate bodies is a common approach. You must make sure that you build these bodies line-to-line with the surrounding bodies. Line-to-line means to make sure the surface of one part exists in the same space of the neighboring body’s surface. Simply put, just make them touch.

Let us use a simple example of a pie that has 4 sections to it. These sections can be differentiated by color or materials, but ultimately you want one solid whole pie to come off the printer. You must build each pie slice as a separate body that collocates with the others – existing in the appropriate position relative to the other bodies in the file. Otherwise you may end up with 4 slices of pie that you will then have to bond together to make whole in a secondary process.

Printing in multiple materials has been around for some time but is becoming more of a necessity every year for the success of our clients. I imagine that if you are reading this blog you too are interested in this necessity.

With the right industry knowledge, creating a multi-body assembly, over-mold, or full color print is simple. Whether you have a completed CAD file or are just starting to design your part, our team is here to help. To start your project, give us a call at 949.474.9222 or send us an email at [email protected].

Related Articles You May Enjoy:

- The Value of Green (& The Other 499,999 Colors You Can 3D Print)

- Assessing Your Prototyping Goals: PolyJet or FDM?

- Top 5 Unexpected Things You Can 3D Print

Meet Mike Stone

Meet Mike Stone

As a Sales Engineer for Purple Porcupine, our prototyping service bureau, Mike helps guide people through the process of bringing their ideas to life. He focuses on the customer’s objectives, while remaining within their timeline and budget. What Mike enjoys most about Purple is working with fun and intelligent colleagues and clients. If you haven’t had the chance to meet Mike yet, stop by the office or connect with him on LinkedIn.