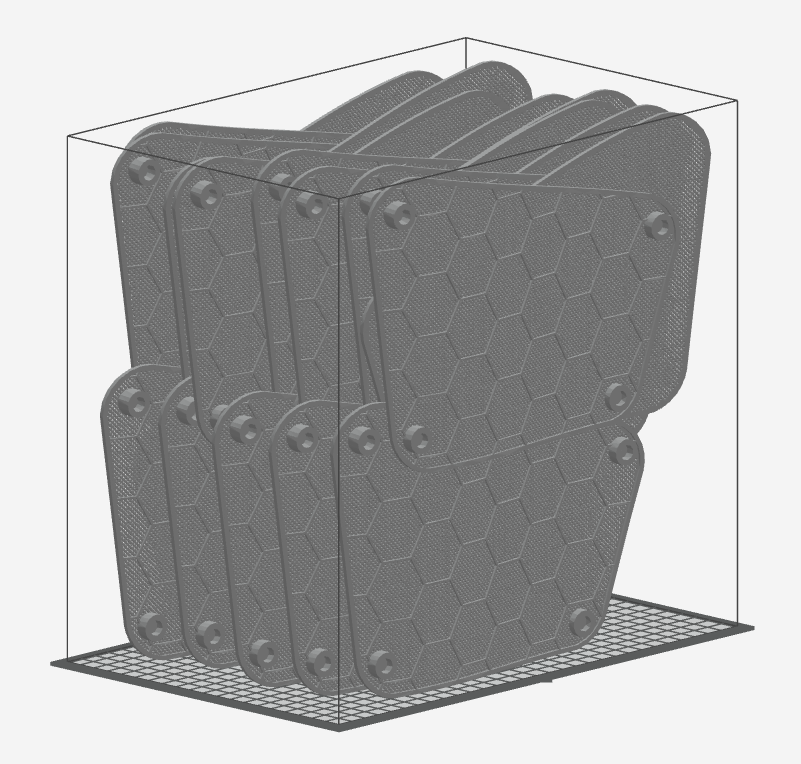

This month’s Part of the Month was chosen by Sales Engineer, Hudson Romain. Hudson picked this speaker cover for its intricate detail and durability. Printed in PA11, the part can be produced in production-levels, as the H350 can create a high-volume of parts with repeatable accuracy.

“I love the practicality of this speaker cover, in that you could use it in almost any car,” says Hudson.

This part was designed by Stratasys Applications Engineer Alec Logeman, who was able to pack 27 of these speaker covers into one 13 hour print on the H350. With the H350, you can print a variety of different parts in a single build. If you add this speaker cover to a pre-planned print, you would have a cost-per-part of around $4.46.

Why PA11? PA11 is an eco-friendly material made from castor oil. It creates parts with high ductility, high impact, and high fatigue resistance. It’s the Model T of 3D materials – available in any color, as long as the color is gray. With the DyeMansion DM60, you can dye PA11 parts a variety of different colors.

“3D printing doesn’t have to be temporary,” says Hudson. And it’s true, with production 3D additive manufacturing and strong materials, your parts can last for years and years. To learn more about your printer or material options, stop by our office or give us a call at 949.474.9222.

Meet Hudson Romain

Meet Sales Engineer, Hudson Romain. Hudson strives to find innovative solutions for designers, manufacturers, and engineers working in every industry. His favorite part about working at Purple Platypus is that he gets to work with people in unique industries, from toys to aerospace.

Out of the office, Hudson enjoys tinkering with engines and circuit boards, playing beach volleyball, and hanging out with friends. If you haven’t had the chance to meet Hudson, be sure to connect with him on LinkedIn!