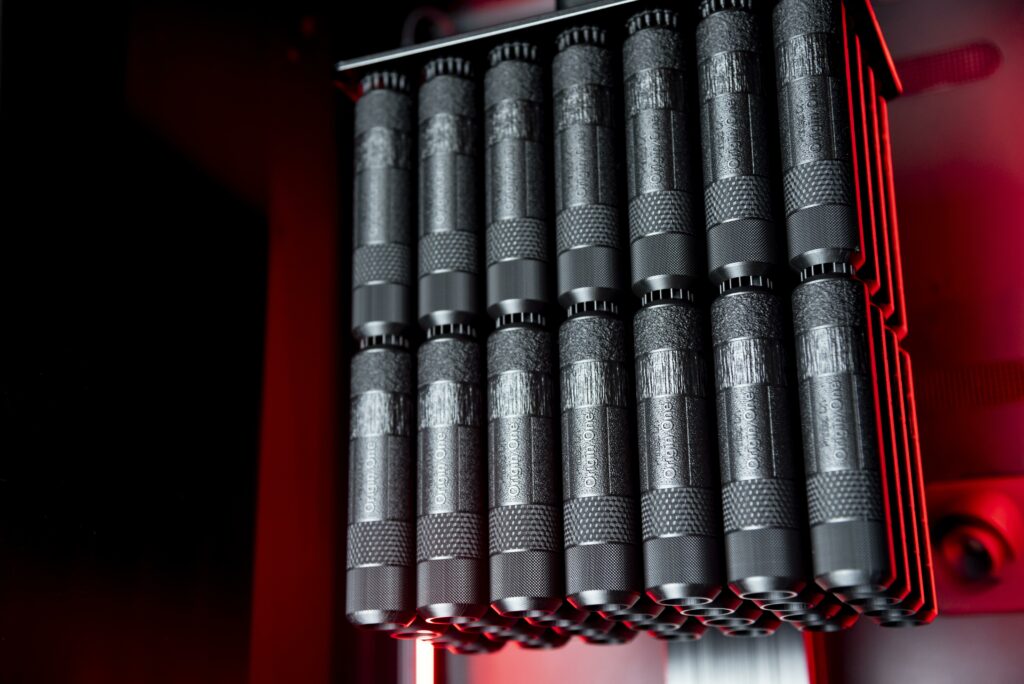

Geoff Varga, a Purple Sales Engineer, picked this month’s part. He is one of the first in the series to choose an Origin One part! This textured handle showcases the detail you can achieve with an Origin One printer.

Geoff said that there were many reasons to why he chose this part, but what really impresses him is the reaction he receives when showing the part to others. “Whenever I show that part to a customer, they just can’t believe that it was 3D printed,” he said. Reasonably so, considering that people in the industry know additive usually comes with unavoidable layer lines. He adds, “So often people are used to seeing layer lines, like in FDM. And when there is a more detail, it’s often for fragile parts like with PolyJet and prototyping.”

The Origin’s ability to print these durable, highly detailed parts in production quantities is where it shines. The Origin One achieves this utilizing Programmable Photo Polymerization (P3) technology, similar to DLP. P3 technology delivers exceptional accuracy, and consistency. You can also print details less than 50 microns in size, with open-source materials.

Beside excelling in creating beautiful single-material prototypes, the Origin One can print end-use parts. How “end-use” are these parts? The Stratasys team has printed everything from a fully functioning scooter (that an adult could ride without issue) to a hammer that can smash asphalt with ease. So, it definitely gets people thinking differently about additive manufacturing.

To learn more about your printer or material options, stop by our office or give us a call at 949.474.9222.

Meet Geoff Varga

As a Sales Engineer for both Purple Platypus and Purple Porcupine, Geoff helps our Arizona customers find the right additive solution for their needs. Geoff’s favorite thing about working at Purple is that he gets to learn something new every day and he is able to help our clients develop innovative products that change the world.

Out of the office, Geoff enjoys volunteering in the community and spending time with his family. If you haven’t had the chance to meet Geoff, be sure to connect with him on LinkedIn!