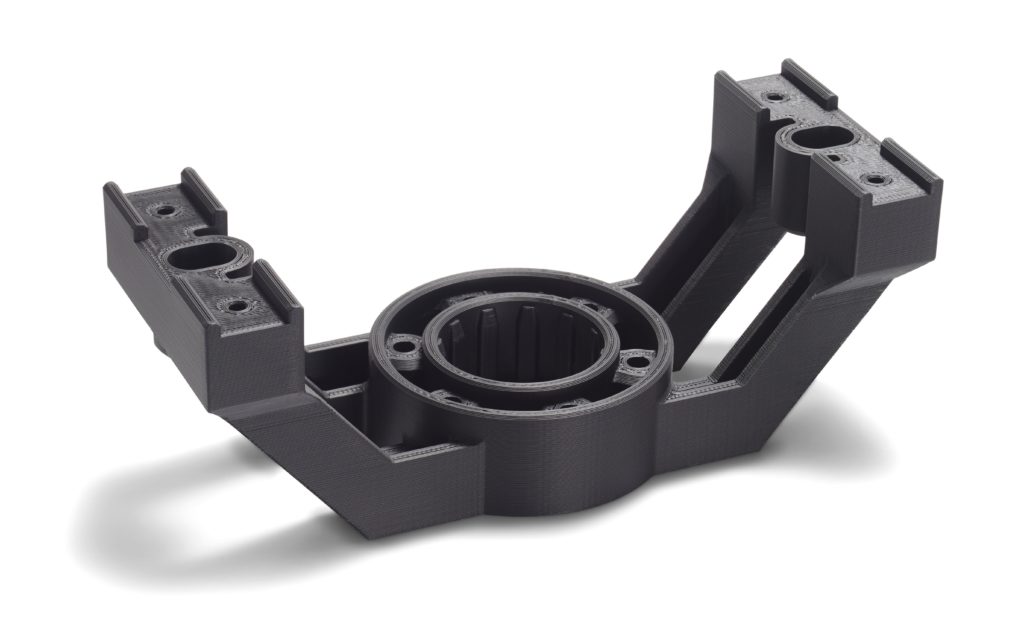

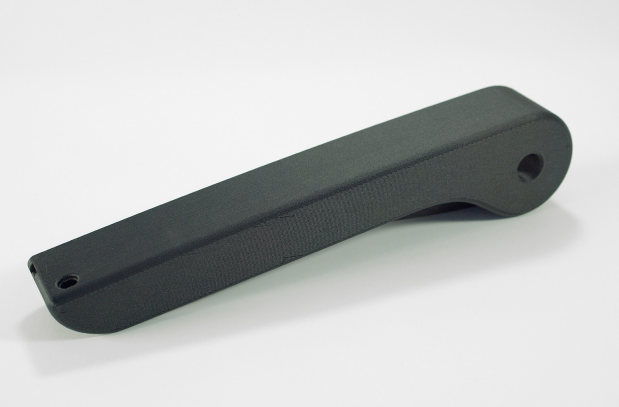

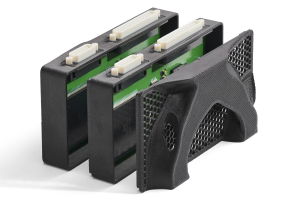

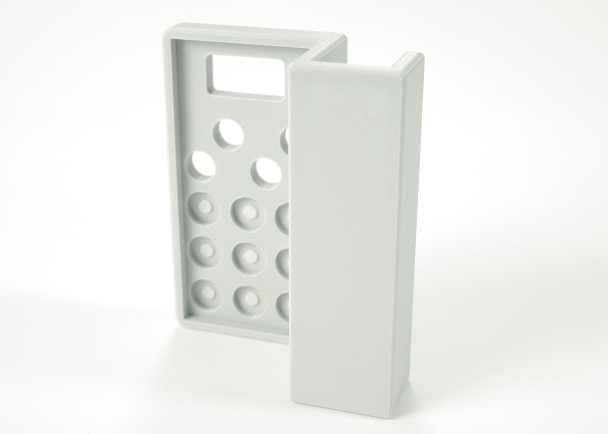

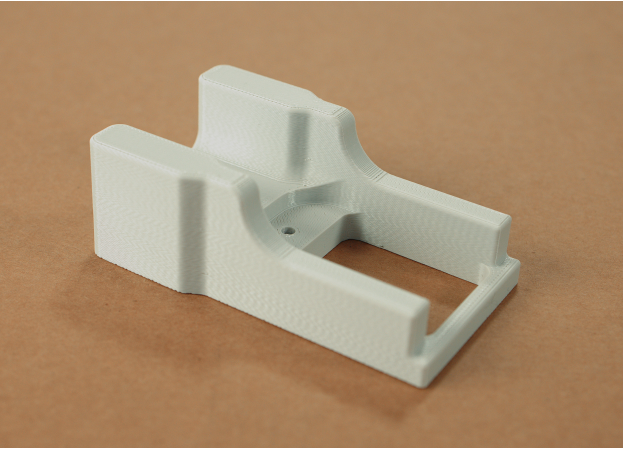

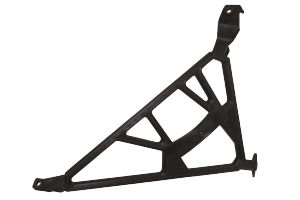

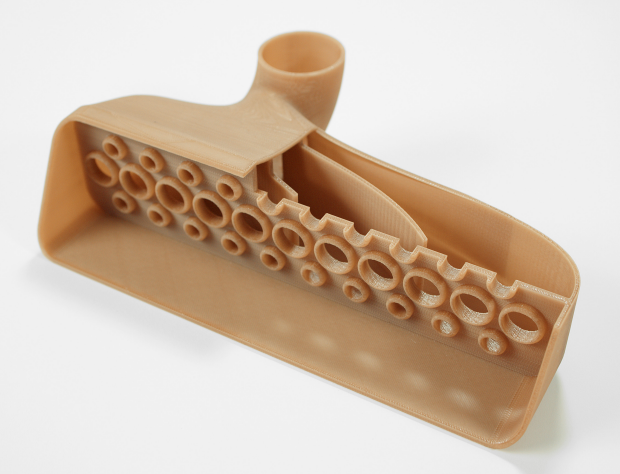

CREATE DURABLE PARTS

FDM Thermoplastic Materials

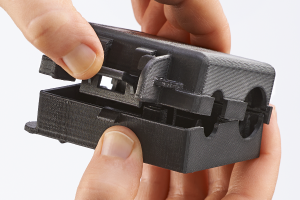

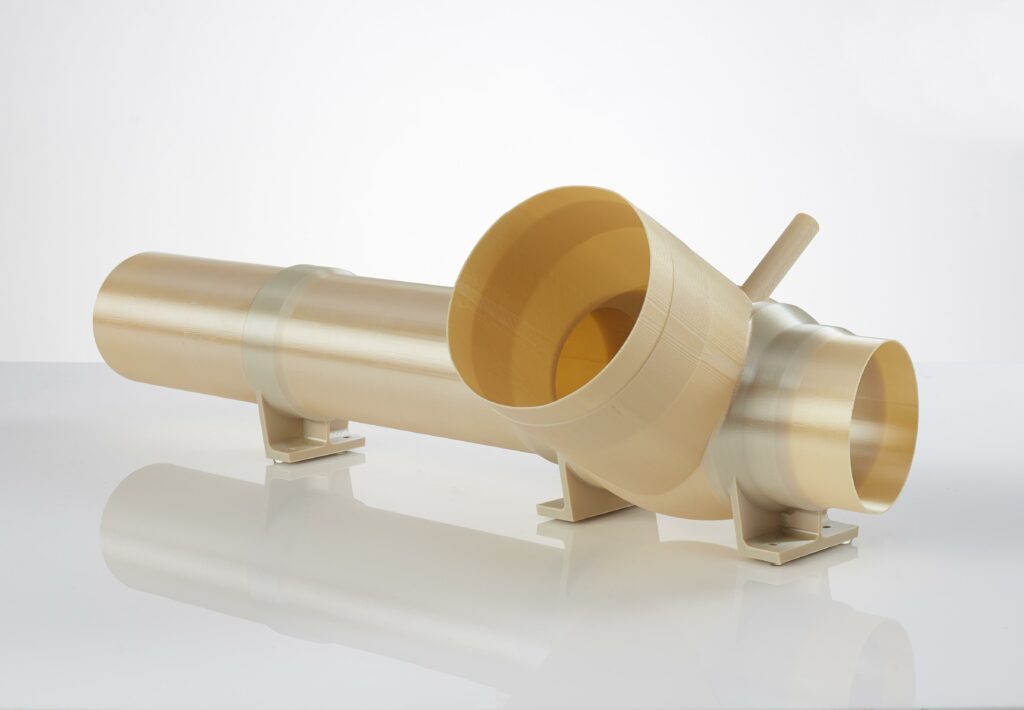

Create prototypes, jigs & fixtures, and end-use parts with our wide selection of FDM material options. Whether you’re looking for a standard or high-performance material, harness the power of Stratasys 3D printing while relying on tested, established thermoplastics.

The Strongest Materials For Your Application

Create durable parts with standard industry recognized thermoplastics. From impact resistance to thermal strength, find a the right plastic for your application. If you have any questions about your FDM options, contact our team today.

LEGEND

Addigy PA6/66

20% Glass-Filled, Fire-Resistant Nylon Polymer

Antero 840CN03

PEKK-Based Thermoplastic With Electrical Properties

Diran 410MF07

Lubricious Nylon-Based Material

FDM HIPS

High Impact Resistant FDM Material

Kimya PC-FR

Flame-Resistant & Good Dimensional Stability

Nylon 6

Combines Strength & Toughness

Nylon-CF10

High Stiffness-to-Weight FDM Material

Nylon 12

Fatigue-Resistant & High Elongation At Break

Nylon 12CF

Highest Flexural Strength of Any FDM Material

PC

Strong Engineering Grade Thermoplastic

PC-ABS

High-Impact Engineering Plastic

PC-ISO

Strong Biocompatible Engineering Grade Plastic

PLA

Renewable Plastic Material

ST-130

Model Material For Sacrificial Tooling

TPU 92A

Flexible Elastomer With Superior Toughness

UTLEM™ 1010 Resin

High Thermal Stability & Chemical Resistance

ULTEM™ 9085 Resin

High Performance, Aerospace-Compliant Thermoplastic

Victrex AM200

High-Performance, Low Melt PAEK Material