FDM's Humble Beginnings

If you’re new to 3D printing like me, you might be wondering what FDM stands for. It’s Fused Deposition Modeling, or as others in the industry might reference it, FFF (Fused Filament Fabrication). Fancy, I know.

FDM technology was created in 1989 by Stratasys founders, husband and wife duo, Scott and Lisa Crump. This technology stems from very humble beginnings. A fatherly Crump wanted to fix his daughter’s favorite toy frog and inspiration struck. He came up with the idea to combine plastic and candle wax to create a filament that he could extrude out of the tip of his hot glue gun, layer by layer. Like other great innovators, this idea came about in his garage. This inspired act of creativity was the very beginning of what would become FDM technology.

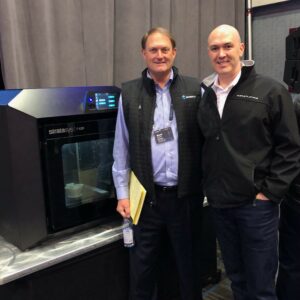

Scott Crump (Left) & Purple Sales Engineer Geoff Varga (Right)

The Evolution of FDM

Fast forward over 30 years and FDM has come a long way from a glue gun, melted wax with plastic, and a garage. Stratasys FDM technology has continued to lead the industry through many evolutions of technology. But pioneers are always striving to improve and develop new applications, and Stratasys has been paving the way ever since.

From the F123 Series, that excel at all stages of the design process, to the Fortus printers, with their accuracy, repeatability, and predictability; each of these machines have their unique features that deliver high value and longstanding results. Enter the newest expansion of FDM technology: the Stratasys F3300.

F3300 Has Entered the Chat

Designed to move FDM forward, the F3300 is the latest innovation in manufacturing. Focused on delivering low cost per part, a boost in productivity, and a reduction in labor, the F3300 is perfect for those looking to improve their workflow. This is FDM reinvented!

There are two key features in the F3300 that our team is excited about: it has an auto-calibration feature, and it prints up to twice as fast as the current FDM offerings. With this, throughput is substantially increased.

How can it print so fast? Faster gantry speeds, multiple extruders, and larger material spools. This reinvention yields improvements in part quality with its integrated material dryers and gantry controls that help regulate material moisture and provide more control over the printing process.

The Stratasys F3300 is best suited for low volume production of parts and manufacturing support fixtures, tools, and high-volume functional prototypes.

Aerospace fixture printed with multiple colors in one print. The F3300 is the first FDM printer to offer this feature.

The Reviews Are In

When Dallas Martin from Toyota Racing Development, the F3300’s first beta customer, was asked for his thoughts on the new printer, he stated, “It’s an amazing machine, I see so much capability in this machine. I think it’s going to take FDM from where it’s at now into the future, and I think its possibilities are endless.”

The F3300 has been living up to, and even exceeding, its hype. Its high throughput and lower cost per part gives customers the chance to excel in their manufacturing process and stay ahead of the competition.

I can’t wait to see who takes advantage of the F3300 next!

If you would like to learn more or if you have any questions, call us at 949.474.9222 or email us at [email protected].

Meet Madeline Moore

Meet 3D Printing Account Specialist, Madeline Moore. Madeline works closely with the Sales and Marketing teams to continue customer experience and manage accounts. Her favorite part about working at Purple is her wonderful coworkers and seeing how additive manufacturing is implemented across a multitude of industries.

Outside of the office, Madeline likes to meditate and do hot yoga. She also loves to listen to psychology podcasts. If you haven’t met Madeline yet, be sure to connect with her on LinkedIn.